Understanding Grooved Prestressed PC Wire: An Essential Component in Modern Construction

Release time:

2025-06-26

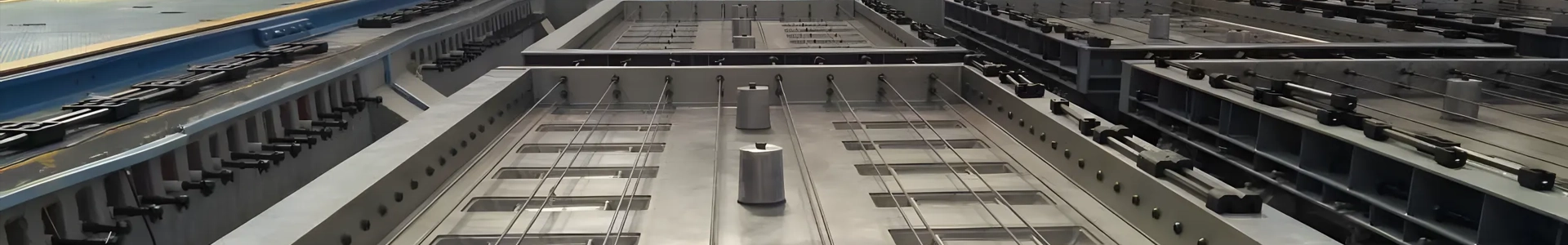

Grooved prestressed PC wire, or prestressed concrete wire, plays a pivotal role in the construction and building materials sector, particularly within the realm of steel materials. This specialized wire is designed to withstand high tensile loads and is commonly used in the production of prestressed concrete elements. The grooved design of this wire enhances its bonding with concrete, improving th

One of the primary benefits of using grooved prestressed PC wire is its ability to provide additional strength to concrete structures. In traditional concrete applications, tensile strength is a significant limitation, as concrete is inherently weak under tension. By incorporating prestressed wires, engineers can effectively counteract this weakness. The grooved surface of the wire increases the surface area in contact with the concrete, allowing for enhanced adhesion and a more efficient transfer of stress. This results in structures that can support greater loads and exhibit improved durability.

The applications of grooved prestressed PC wire extend across various construction sectors, including bridges, high-rise buildings, and parking structures. In bridge construction, for instance, the use of prestressed wire enables the creation of longer spans without the need for additional support columns, thereby optimizing space and reducing construction costs. In high-rise buildings, the ability to use thinner concrete slabs—thanks to the enhanced tensile strength provided by prestressing—allows for more flexible architectural designs and lighter structures.

Moreover, the grooved design contributes to the wire's performance under dynamic loads, such as those experienced during seismic events. The improved anchoring capacity ensures that the prestressed wire effectively mitigates the forces acting on the structure, enhancing overall safety and resilience.

From a manufacturing perspective, grooved prestressed PC wire is produced under stringent quality control measures to ensure consistency and reliability. The wire is typically made from high-strength steel, which undergoes various tests to confirm its tensile properties and resistance to fatigue. Such rigorous standards ensure that the wire performs effectively in demanding construction applications.

In summary, grooved prestressed PC wire is an indispensable component in modern construction, offering enhanced strength, improved bonding with concrete, and a wide range of applications. Its ability to transform traditional concrete into high-performance structural elements makes it a critical material for engineers and architects dedicated to creating safe and innovative structures. Understanding the properties and benefits of this wire not only aids professionals in their projects but also contributes to the advancement of construction techniques.

Latest News

Why Choose Uncoated Prestressed Wire for Your Next Building Project?

Why Choose Uncoated Prestressed Wire for Your Next Building Project? Understanding Uncoated Prestressed Wire In the world of construction and architectural design, the materials you choose can significantly impact the overall success and longevity of a project. One material that stands out in the realm of concrete reinforcement is uncoated prestressed wire. This article delves into the advantages

2025-08-10

Understanding Uncoated Prestressed Wire: A Key Component in Construction

Uncoated prestressed wire is a crucial element in the construction and decorative materials sector, particularly in steel applications. This type of wire is designed to provide enhanced structural performance by being tensioned prior to the application of loads, thus improving the overall strength and durability of concrete structures. The primary advantage of uncoated prestressed wire lies in it

2025-08-07

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction In the dynamic world of construction, material choices can significantly influence project outcomes. Among the myriad of options available, uncoated prestressed wire has emerged as a pivotal component in modern engineering. In this comprehensive article, we will delve into the multifaceted benefits of uncoated prestressed w

2025-08-04

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture Introduction to Prestressed Reinforced Ribbed Wire Prestressed reinforced ribbed wire is a crucial material in the field of modern architecture and construction. It combines the advantages of prestressing technology with the physical properties of ribbed wire, enhancing the strength and durability of concrete structures.

2025-07-29

Understanding Prestressed Reinforced Ribbed Wire: A Key Component in Modern Construction

Prestressed reinforced ribbed wire is an innovative material widely used in the construction and decoration sectors, particularly within steel materials and wire ropes. This specialized wire combines the benefits of prestressing techniques with ribbed surface characteristics to provide superior strength, flexibility, and durability. Understanding the properties and applications of prestressed rein

2025-07-26

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction Table of Contents 1. Introduction to Prestressed Reinforced Ribbed Wire 2. What is Prestressed Reinforced Ribbed Wire? 3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire 3.1 Enhanced Strength and Load-Bearing Capacity 3.2 Durability and Longevity 3.3 Cost-Effective

2025-07-23