Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture

Release time:

2025-07-29

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture Introduction to Prestressed Reinforced Ribbed Wire Prestressed reinforced ribbed wire is a crucial material in the field of modern architecture and construction. It combines the advantages of prestressing technology with the physical properties of ribbed wire, enhancing the strength and durability of concrete structures.

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture

Introduction to Prestressed Reinforced Ribbed Wire

Prestressed reinforced ribbed wire is a crucial material in the field of modern architecture and construction. It combines the advantages of prestressing technology with the physical properties of ribbed wire, enhancing the strength and durability of concrete structures. This article explores the various applications of this innovative material, highlighting its versatility and importance in contemporary architectural practices.

Understanding Prestressing: A Fundamental Concept

To appreciate the applications of prestressed reinforced ribbed wire, it is essential to understand the concept of prestressing. This technique involves the application of a pre-compressive force to a concrete element, allowing it to withstand tension and compression loads more effectively. By incorporating prestressed reinforced ribbed wire into concrete, architects and engineers can create structures that are not only stronger but also lighter, leading to significant material savings.

Advantages of Using Prestressed Reinforced Ribbed Wire

The benefits of prestressed reinforced ribbed wire are numerous and can dramatically impact the design and longevity of buildings. These advantages include:

- **Enhanced Load-Bearing Capacity**: The wires distribute loads more evenly, improving the overall strength of the structure.

- **Reduced Cracking**: By counteracting tensile forces, this material minimizes the risk of cracks in concrete, leading to longer-lasting constructions.

- **Improved Durability**: Structures using prestressed reinforced ribbed wire exhibit greater resistance to environmental factors, such as moisture and temperature fluctuations.

- **Cost Efficiency**: The ability to use less material without sacrificing strength translates to lower construction costs.

Key Applications of Prestressed Reinforced Ribbed Wire

Now that we understand the basics, let’s dive into the specific applications of prestressed reinforced ribbed wire in modern architecture.

1. High-Rise Buildings

High-rise buildings are a prominent application of prestressed reinforced ribbed wire. The structural integrity required for such tall constructions demands innovative materials that can handle substantial loads. Prestressed ribbed wire improves the load distribution across the concrete floors and walls, allowing for taller and more slender designs without compromising safety.

Case Study: Iconic Skyscrapers

Many iconic skyscrapers utilize this technology to ensure stability and durability. For instance, the Burj Khalifa in Dubai incorporates advanced prestressing techniques to achieve its towering height and unique design.

2. Bridges and Overpasses

Bridges often face dynamic loads from vehicles and environmental conditions. Prestressed reinforced ribbed wire enhances the resilience of bridge structures, allowing them to span greater distances without the need for excessive support columns.

Innovative Bridge Designs

Modern architects employ this material in cable-stayed and suspension bridges, where the tension in cables is crucial for maintaining structural integrity. The use of ribbed wire enables these designs to be both aesthetically pleasing and functionally effective.

3. Stadiums and Auditoriums

The vast open spaces required in stadiums and auditoriums present unique challenges in terms of structural support. Prestressed reinforced ribbed wire allows for the creation of expansive roofs and grandstands that can support significant loads while minimizing the number of supporting columns.

Design Considerations for Large Venues

Architects can create visually stunning and acoustically optimized environments by leveraging the properties of prestressed reinforced ribbed wire, leading to better spectator experiences.

4. Parking Structures

In urban environments, parking structures must maximize space while ensuring safety and durability. The use of prestressed reinforced ribbed wire allows for thinner concrete slabs and reduced column sizes, creating more open parking areas.

Efficiency in Design

This application is particularly essential in cities where land is at a premium. By optimizing the structural design with ribbed wire, architects can provide efficient and effective solutions for urban parking challenges.

5. Residential Buildings

Prestressed reinforced ribbed wire is not limited to commercial projects; it also plays a key role in residential architecture. It offers homeowners the opportunity to build larger living spaces while ensuring safety and structural integrity.

Sustainable Housing Solutions

With the increasing emphasis on sustainable architecture, integrating this material into residential design can lead to fewer resources needed for construction, thus promoting eco-friendly building practices.

Innovative Techniques in Using Prestressed Reinforced Ribbed Wire

As technology advances, so do the methods for employing prestressed reinforced ribbed wire in construction. Here are some innovative techniques gaining traction in the industry.

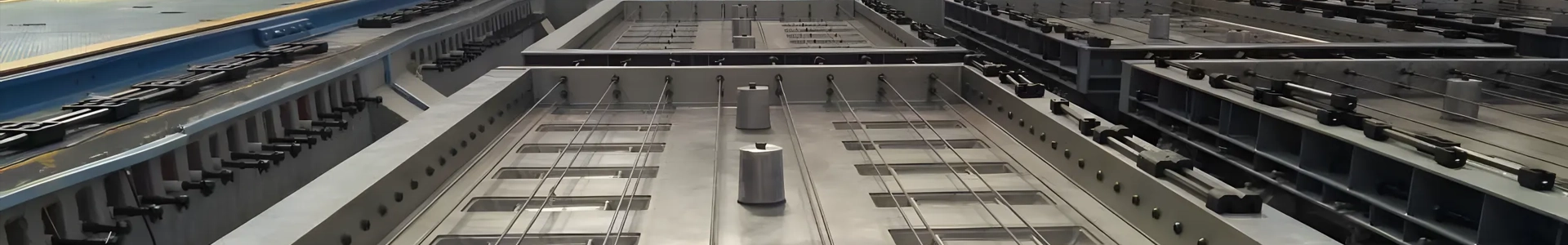

1. Advanced Production Techniques

The production of prestressed reinforced ribbed wire has evolved, utilizing automated processes to ensure consistent quality and performance. These advancements allow for more precise engineering, reducing waste and optimizing material usage.

2. Smart Technology Integration

Incorporating smart technology into the design and monitoring of structures using prestressed reinforced ribbed wire can enhance safety and efficiency. Sensors can track structural integrity and alert engineers to potential issues before they escalate.

3. Modular Construction

The trend towards modular construction is also benefiting from prestressed reinforced ribbed wire. Prefabricated components can be manufactured off-site and assembled quickly, resulting in faster project completion and reduced labor costs.

Challenges and Considerations in Using Prestressed Reinforced Ribbed Wire

While the benefits of prestressed reinforced ribbed wire are significant, there are also challenges that architects and engineers must address.

1. Initial Costs

The initial investment for utilizing prestressed reinforced ribbed wire can be higher than traditional materials. However, the long-term savings and benefits often outweigh these upfront costs.

2. Specialized Knowledge Required

The design and installation of prestressed systems require specialized knowledge and experience. Ensuring that teams are well-trained in these techniques is crucial for successful implementation.

Future Trends in Prestressed Reinforced Ribbed Wire Usage

As architectural practices continue to evolve, the future of prestressed reinforced ribbed wire looks promising.

1. Sustainability Focus

With a growing emphasis on sustainable construction, the use of prestressed reinforced ribbed wire aligns perfectly with eco-friendly design principles. Its ability to reduce material usage and enhance durability contributes to greener building practices.

2. Increased Use in Seismic Zones

As urban populations expand, buildings in seismic zones require robust solutions. The properties of prestressed reinforced ribbed wire make it an ideal candidate for enhancing the earthquake resistance of structures.

Frequently Asked Questions (FAQs)

1. What is prestressed reinforced ribbed wire?

Prestressed reinforced ribbed wire is a type of steel wire used in concrete construction, designed to enhance the strength and durability of concrete structures by applying pre-compressive forces.

2. How does prestressing improve concrete performance?

Prestressing counteracts tensile forces in concrete, reducing the likelihood of cracking and allowing for longer spans and lighter structures.

3. Where is prestressed reinforced ribbed wire commonly used?

It is widely used in high-rise buildings, bridges, stadiums, parking structures, and residential buildings.

4. What are the cost implications of using prestressed reinforced ribbed wire?

While the initial costs can be higher, the long-term savings due to reduced material usage and enhanced durability often justify the investment.

5. Can prestressed reinforced ribbed wire be used in seismic areas?

Yes, it is increasingly being used in seismic zones due to its ability to improve the earthquake resistance of structures.

Conclusion

Prestressed reinforced ribbed wire is a cornerstone of modern architectural innovation. Its unique properties enable architects and engineers to design structures that are not only aesthetically pleasing but also incredibly strong and durable. As we navigate the challenges of urbanization and sustainability, the applications of this material will undoubtedly expand, paving the way for a new era in construction. By embracing the potential of prestressed reinforced ribbed wire, the architectural community can continue to push the boundaries of design while ensuring the safety and longevity of our built environments.

Latest News

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture Introduction to Prestressed Reinforced Ribbed Wire Prestressed reinforced ribbed wire is a crucial material in the field of modern architecture and construction. It combines the advantages of prestressing technology with the physical properties of ribbed wire, enhancing the strength and durability of concrete structures.

2025-07-29

Understanding Prestressed Reinforced Ribbed Wire: A Key Component in Modern Construction

Prestressed reinforced ribbed wire is an innovative material widely used in the construction and decoration sectors, particularly within steel materials and wire ropes. This specialized wire combines the benefits of prestressing techniques with ribbed surface characteristics to provide superior strength, flexibility, and durability. Understanding the properties and applications of prestressed rein

2025-07-26

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction Table of Contents 1. Introduction to Prestressed Reinforced Ribbed Wire 2. What is Prestressed Reinforced Ribbed Wire? 3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire 3.1 Enhanced Strength and Load-Bearing Capacity 3.2 Durability and Longevity 3.3 Cost-Effective

2025-07-23

Understanding High-Tensile Indented PC Wire: A Key Material in Construction

High-tensile indented PC wire, short for prestressed concrete wire, is an innovative steel material that has gained significant attention in the construction industry due to its excellent strength-to-weight ratio and durability. This wire is manufactured with indents on its surface, which enhances its bond with concrete, making it an ideal choice for various structural applications. One of the sta

2025-07-20

High-Tensile Indented PC Wire: The Backbone of Earthquake-Resistant Structures

High-Tensile Indented PC Wire: Essential for Earthquake-Resistant Structures Table of Contents 1. Introduction to High-Tensile Indented PC Wire 2. Properties of High-Tensile Indented PC Wire 3. Benefits of Using High-Tensile Indented PC Wire in Construction 4. Applications of High-Tensile Indented PC Wire in Earthquake-Resistant Structures 5. Comparative Analysis: High-Tensile

2025-07-17

Understanding High-Tensile Indented PC Wire: Strength and Versatility in Construction

High-tensile indented PC wire, or prestressed concrete wire, is engineered to provide exceptional strength and flexibility, making it a vital material in various construction applications. The term "high-tensile" refers to the wire’s ability to withstand significant tensile forces without breaking, ensuring its reliability in structural applications. The "indented" feature enhances its adhesion pr

2025-07-14