Understanding Prestressed Reinforced Ribbed Wire: A Key Component in Modern Construction

Release time:

2025-07-26

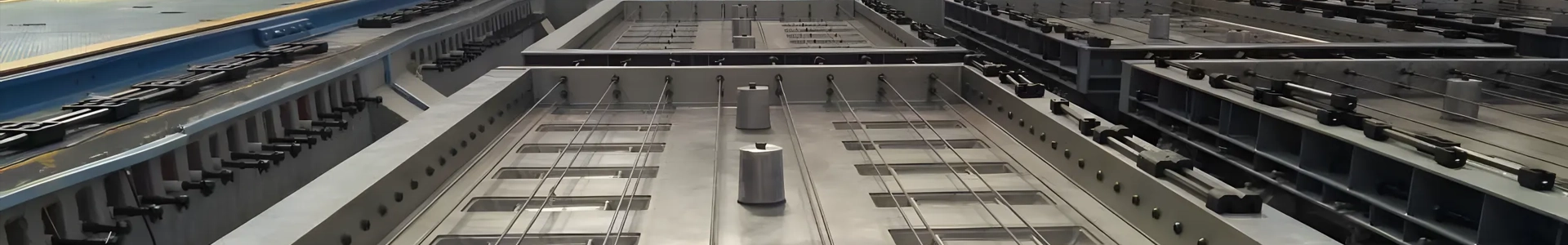

Prestressed reinforced ribbed wire is an innovative material widely used in the construction and decoration sectors, particularly within steel materials and wire ropes. This specialized wire combines the benefits of prestressing techniques with ribbed surface characteristics to provide superior strength, flexibility, and durability. Understanding the properties and applications of prestressed rein

At its core, prestressed reinforced ribbed wire is designed to withstand tensile forces effectively. The ribbed surface plays a crucial role by increasing the bond between the wire and the surrounding concrete or other materials. This superior bond strength minimizes the risk of slippage, enhancing the overall structural integrity of construction elements such as beams, slabs, and columns. The prestressing process involves applying a pre-tensioning force to the wire, which not only offsets the tensile stresses that occur during service but also allows for thinner slabs and lighter structures, providing cost savings in materials and labor.

One of the primary advantages of using prestressed reinforced ribbed wire in construction is its ability to reduce deflection and control cracking in concrete structures. When used in combination with concrete, the wire absorbs tensile stresses, allowing the concrete to focus on compressive loads. This synergy results in enhanced load-carrying capacity and longevity of the structure, making it particularly valuable in high-load scenarios such as bridges and high-rise buildings.

Furthermore, the versatility of prestressed reinforced ribbed wire makes it suitable for various applications. It is commonly employed in the manufacturing of precast concrete products, where precise control over material properties is essential. Additionally, this wire is ideal for retrofitting existing structures, providing a method to extend their lifespan and improve performance without significant overhauls.

From an environmental perspective, utilizing prestressed reinforced ribbed wire contributes to sustainability in construction. By enabling lighter structures, less material is required, which can lead to reduced carbon footprints and resource usage. Moreover, the durability of such systems minimizes the need for frequent repairs and replacements, further supporting eco-friendly building practices.

In summary, prestressed reinforced ribbed wire is a vital component in modern construction, offering enhanced structural performance, versatility, and sustainability. As construction technology continues to evolve, the importance of such innovative materials cannot be overstated. Understanding their applications and benefits enables professionals in the industry to make informed decisions that improve project outcomes and contribute to the resilience of infrastructure.

Latest News

Understanding Prestressed Reinforced Ribbed Wire: A Key Component in Modern Construction

Prestressed reinforced ribbed wire is an innovative material widely used in the construction and decoration sectors, particularly within steel materials and wire ropes. This specialized wire combines the benefits of prestressing techniques with ribbed surface characteristics to provide superior strength, flexibility, and durability. Understanding the properties and applications of prestressed rein

2025-07-26

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction Table of Contents 1. Introduction to Prestressed Reinforced Ribbed Wire 2. What is Prestressed Reinforced Ribbed Wire? 3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire 3.1 Enhanced Strength and Load-Bearing Capacity 3.2 Durability and Longevity 3.3 Cost-Effective

2025-07-23

Understanding High-Tensile Indented PC Wire: A Key Material in Construction

High-tensile indented PC wire, short for prestressed concrete wire, is an innovative steel material that has gained significant attention in the construction industry due to its excellent strength-to-weight ratio and durability. This wire is manufactured with indents on its surface, which enhances its bond with concrete, making it an ideal choice for various structural applications. One of the sta

2025-07-20

High-Tensile Indented PC Wire: The Backbone of Earthquake-Resistant Structures

High-Tensile Indented PC Wire: Essential for Earthquake-Resistant Structures Table of Contents 1. Introduction to High-Tensile Indented PC Wire 2. Properties of High-Tensile Indented PC Wire 3. Benefits of Using High-Tensile Indented PC Wire in Construction 4. Applications of High-Tensile Indented PC Wire in Earthquake-Resistant Structures 5. Comparative Analysis: High-Tensile

2025-07-17

Understanding High-Tensile Indented PC Wire: Strength and Versatility in Construction

High-tensile indented PC wire, or prestressed concrete wire, is engineered to provide exceptional strength and flexibility, making it a vital material in various construction applications. The term "high-tensile" refers to the wire’s ability to withstand significant tensile forces without breaking, ensuring its reliability in structural applications. The "indented" feature enhances its adhesion pr

2025-07-14

Understanding Prestressed Spiral Rib Wire: A Comprehensive Overview for Professionals

--- Prestressed spiral rib wire is an advanced type of steel wire, essential in the construction and decoration sectors, particularly within the realm of prestressed concrete. This specialized wire is designed to enhance the load-bearing capacity and overall performance of concrete structures. Its unique spiral rib design allows for better bonding with concrete, ensuring that the wire effectively

2025-07-08