Understanding Prestressed Spiral Rib Wire: A Comprehensive Overview for Professionals

Release time:

2025-07-08

--- Prestressed spiral rib wire is an advanced type of steel wire, essential in the construction and decoration sectors, particularly within the realm of prestressed concrete. This specialized wire is designed to enhance the load-bearing capacity and overall performance of concrete structures. Its unique spiral rib design allows for better bonding with concrete, ensuring that the wire effectively

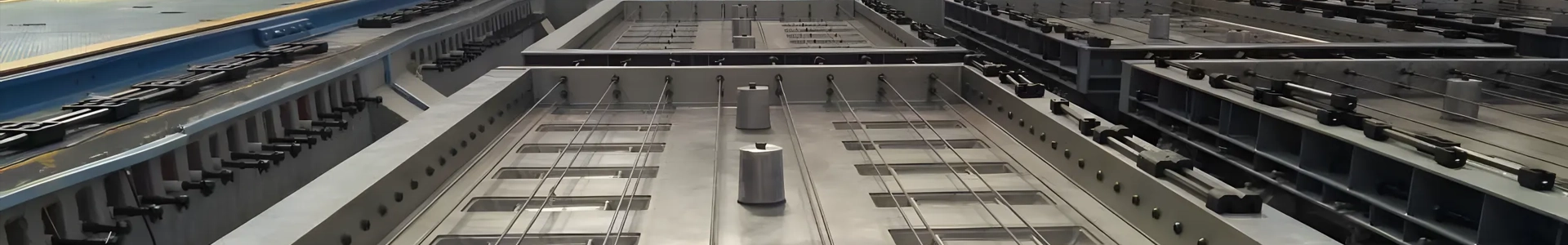

Prestressed spiral rib wire is an advanced type of steel wire, essential in the construction and decoration sectors, particularly within the realm of prestressed concrete. This specialized wire is designed to enhance the load-bearing capacity and overall performance of concrete structures. Its unique spiral rib design allows for better bonding with concrete, ensuring that the wire effectively transfers stress and load across the structure, which is fundamental in modern engineering practices.

One of the primary applications of prestressed spiral rib wire is in the manufacturing of precast concrete products, such as beams, slabs, and girders. The ribbed surface of the wire increases friction between the wire and the concrete, leading to superior adhesion. This characteristic is vital when considering the dynamic loads that structures may encounter over their lifetime. By incorporating prestressed spiral rib wire, engineers can significantly improve the durability and lifespan of concrete elements, making them more resistant to cracking and deformation.

Moreover, the prestressing process involves tensioning the wire before or after the concrete is poured, which induces compressive stresses in the concrete. This innovative approach not only maximizes the load-bearing capacity of the concrete but also minimizes the risk of tensile failures. In high-rise buildings and large-span bridges, for instance, this technique is particularly beneficial, as it allows for longer spans and thinner concrete sections, leading to material savings and reduced weight.

Another significant advantage of prestressed spiral rib wire is its versatility. It can be utilized in various applications, including civil engineering projects, industrial construction, and even decorative elements where both aesthetics and structural integrity are paramount. The adaptability of this material makes it a preferred choice among engineers and architects who are striving for innovative solutions in their designs.

The use of prestressed spiral rib wire is also aligned with the current trends in sustainable construction. By enabling the creation of lighter and more efficient structures, this type of wire contributes to reducing material waste and energy consumption during the construction process. As sustainability becomes increasingly important in the industry, the adoption of advanced materials like prestressed spiral rib wire is expected to grow.

In summary, prestressed spiral rib wire serves as a critical component in enhancing the performance and reliability of concrete structures. Its unique design and properties not only improve the structural integrity but also contribute to more sustainable building practices. As industry professionals continue to seek innovative materials that meet modern engineering demands, prestressed spiral rib wire stands out as a key player in the construction and decorative materials sector.

Latest News

Understanding Prestressed Spiral Rib Wire: A Comprehensive Overview for Professionals

--- Prestressed spiral rib wire is an advanced type of steel wire, essential in the construction and decoration sectors, particularly within the realm of prestressed concrete. This specialized wire is designed to enhance the load-bearing capacity and overall performance of concrete structures. Its unique spiral rib design allows for better bonding with concrete, ensuring that the wire effectively

2025-07-08

Why Choose Prestressed Spiral Rib Wire for Your Building Projects?

Why Choose Prestressed Spiral Rib Wire for Your Building Projects? Table of Contents Introduction to Prestressed Spiral Rib Wire Benefits of Using Prestressed Spiral Rib Wire High Strength and Durability Enhanced Flexibility and Adaptability Cost Efficiency and Long-Term Savings Applications of Prestressed Spiral Rib Wire

2025-07-05

Understanding Prestressed Spiral Rib Wire: A Key Component in Modern Construction

Prestressed spiral rib wire is a specialized type of steel wire that plays a significant role in modern construction and engineering projects. This material is designed to enhance the overall structural integrity of concrete elements, making it a vital component in various applications, particularly in prestressed concrete. The unique spiral rib design of the wire provides additional surface area

2025-07-02

Exploring the Benefits of Prestressed Spiral Rib Wire in Construction

Exploring the Benefits of Prestressed Spiral Rib Wire in Construction Table of Contents 1. Introduction to Prestressed Spiral Rib Wire 2. What is Prestressed Spiral Rib Wire? 3. Advantages of Using Prestressed Spiral Rib Wire 3.1 Increased Strength and Durability 3.2 Cost-Effectiveness 3.3 Design Flexibility 3.4 Reduced Construc

2025-06-29

Understanding Grooved Prestressed PC Wire: An Essential Component in Modern Construction

Grooved prestressed PC wire, or prestressed concrete wire, plays a pivotal role in the construction and building materials sector, particularly within the realm of steel materials. This specialized wire is designed to withstand high tensile loads and is commonly used in the production of prestressed concrete elements. The grooved design of this wire enhances its bonding with concrete, improving th

2025-06-26

Why Grooved Prestressed PC Wire is Essential for Modern Building Projects

Understanding Grooved Prestressed PC Wire: The Backbone of Modern Construction When it comes to modern building projects, **grooved prestressed PC wire** stands out as an essential component. This innovative material, designed specifically for high-performance applications, helps engineers and builders achieve optimal structural integrity and durability. In this article, we will explore the multif

2025-06-23