Exploring the Benefits of Prestressed Spiral Rib Wire in Construction

Release time:

2025-06-29

Exploring the Benefits of Prestressed Spiral Rib Wire in Construction Table of Contents 1. Introduction to Prestressed Spiral Rib Wire 2. What is Prestressed Spiral Rib Wire? 3. Advantages of Using Prestressed Spiral Rib Wire 3.1 Increased Strength and Durability 3.2 Cost-Effectiveness 3.3 Design Flexibility 3.4 Reduced Construc

Exploring the Benefits of Prestressed Spiral Rib Wire in Construction

Table of Contents

- 1. Introduction to Prestressed Spiral Rib Wire

- 2. What is Prestressed Spiral Rib Wire?

- 3. Advantages of Using Prestressed Spiral Rib Wire

- 3.1 Increased Strength and Durability

- 3.2 Cost-Effectiveness

- 3.3 Design Flexibility

- 3.4 Reduced Construction Time

- 3.5 Enhanced Safety

- 4. Applications of Prestressed Spiral Rib Wire in Construction

- 5. Comparison with Other Construction Materials

- 6. Installation Techniques for Prestressed Spiral Rib Wire

- 7. Environmental Impact of Using Prestressed Spiral Rib Wire

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to Prestressed Spiral Rib Wire

In the ever-evolving landscape of construction, the need for materials that offer superior performance and cost savings is paramount. Prestressed spiral rib wire has emerged as a revolutionary solution for modern building projects. This article will explore the myriad benefits of this innovative material, shedding light on its composition, advantages, applications, and installation techniques.

2. What is Prestressed Spiral Rib Wire?

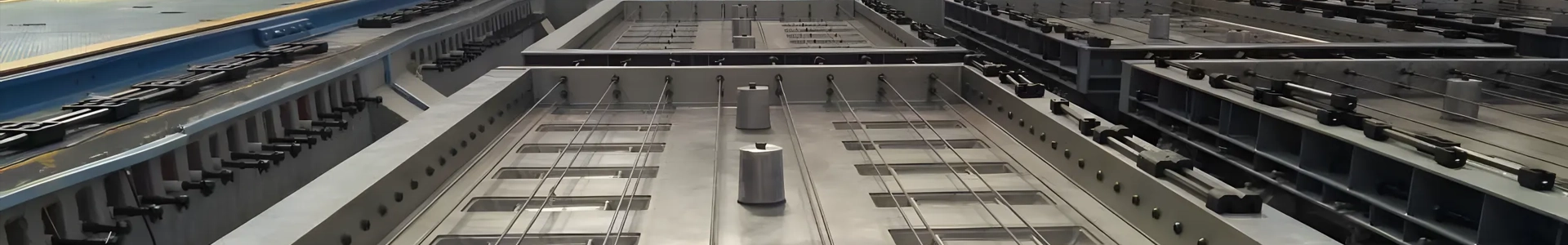

Prestressed spiral rib wire is a high-strength steel wire characterized by its unique spiral ribbed design. This design increases the surface area for bonding with concrete, improving the tensile strength of structures. The "prestressed" aspect refers to the process of applying tension to the wire before it is embedded in concrete, allowing it to withstand greater loads and resist deformation.

This wire is commonly used in various construction applications, including bridges, high-rise buildings, and precast concrete elements. Its properties make it an essential component for achieving durability and structural integrity in demanding environments.

3. Advantages of Using Prestressed Spiral Rib Wire

The advantages of prestressed spiral rib wire are numerous, making it a preferred choice among construction professionals. Below are some of the key benefits:

3.1 Increased Strength and Durability

One of the most significant advantages of prestressed spiral rib wire is its enhanced strength and durability. The prestressing process allows the wire to handle high tensile forces, which means structures can support heavier loads without the risk of failure. This property is crucial in areas prone to seismic activity or heavy winds, as it provides added safety and resilience.

3.2 Cost-Effectiveness

Using prestressed spiral rib wire can lead to substantial cost savings during construction. Its high tensile strength allows for the design of slimmer structural elements, which can reduce the amount of concrete and steel required. Furthermore, the durability of the wire reduces maintenance costs over time, making it a wise investment for long-term projects.

3.3 Design Flexibility

Prestressed spiral rib wire offers remarkable design flexibility. Engineers and architects can create innovative structures that were previously deemed impossible. The wire can be adapted to suit various shapes and configurations, allowing for more creative and aesthetically pleasing designs without compromising structural integrity.

3.4 Reduced Construction Time

Time is often a critical factor in construction projects. The ease of installation associated with prestressed spiral rib wire can significantly expedite the construction process. Since the wire can be pre-tensioned off-site, it simplifies on-site operations and reduces labor costs. As a result, projects can be completed more quickly, leading to faster returns on investment.

3.5 Enhanced Safety

Safety is one of the highest priorities in construction. The robust nature of prestressed spiral rib wire contributes to the overall safety of structures. Its ability to withstand extreme loads and resist cracking under pressure ensures that buildings and other infrastructures remain safe for public use. Additionally, the reduction in material use leads to lighter structures that are easier to manage on-site, further promoting safety during construction.

4. Applications of Prestressed Spiral Rib Wire in Construction

Prestressed spiral rib wire is employed in a variety of construction applications. Some of the most notable include:

- **Bridges**: Its high strength enables the construction of longer spans without the need for numerous supports, enhancing the aesthetic appeal and functionality of bridge designs.

- **High-rise Buildings**: The wire supports vertical loads in skyscrapers, allowing architects to push the limits of height and design.

- **Precast Concrete Elements**: Used in precast applications, it improves the load-bearing capacity and overall performance of concrete panels.

- **Water Retaining Structures**: Essential in tanks and dams, prestressed spiral rib wire helps maintain structural integrity under water pressure.

5. Comparison with Other Construction Materials

When comparing prestressed spiral rib wire with traditional reinforcement methods, several key differences emerge. Traditional steel reinforcement bars (rebar) lack the prestressing capabilities of spiral rib wire, often resulting in bulkier designs and increased material usage. Additionally, spiral rib wire's superior bonding with concrete enhances the overall performance of structures compared to standard rebar.

Furthermore, while other materials may require frequent maintenance, the durability of prestressed spiral rib wire reduces the need for ongoing care, contributing to its long-term cost-effectiveness.

6. Installation Techniques for Prestressed Spiral Rib Wire

The installation of prestressed spiral rib wire involves specific techniques to ensure optimal performance. Typically, the process includes:

1. **Pre-tensioning**: The wire is tensioned before being placed in the concrete, creating a compressive force that enhances structural integrity.

2. **Placement**: The wire is positioned in forms before the concrete is poured, ensuring a snug fit that promotes effective bonding.

3. **Curing**: After the concrete has set, the tension is released, allowing the wire to compress the concrete, thereby enhancing its load-bearing capacity.

Effective installation is crucial, and it is recommended that trained professionals perform these tasks to guarantee safety and structural reliability.

7. Environmental Impact of Using Prestressed Spiral Rib Wire

The use of prestressed spiral rib wire is not only beneficial from a structural perspective but also offers environmental advantages. By reducing the amount of concrete and steel needed, it contributes to lower carbon emissions associated with material production. Additionally, its durability means that structures last longer, decreasing the frequency of repairs and the associated environmental impact. This makes prestressed spiral rib wire an eco-friendly choice for sustainable construction practices.

8. Frequently Asked Questions (FAQs)

8.1 What is the primary benefit of using prestressed spiral rib wire?

The primary benefit of prestressed spiral rib wire is its enhanced strength and durability, allowing for the construction of safer, more resilient structures.

8.2 How does prestressed spiral rib wire differ from traditional rebar?

Prestressed spiral rib wire is pre-tensioned, providing superior tensile strength compared to traditional rebar, which lacks this prestressing capability.

8.3 Is the installation of prestressed spiral rib wire complex?

While installation techniques require specific knowledge and skills, trained professionals can efficiently manage the process to ensure optimal results.

8.4 Can prestressed spiral rib wire be reused?

In many cases, prestressed spiral rib wire can be reused or recycled, further enhancing its sustainability profile.

8.5 What types of structures benefit most from prestressed spiral rib wire?

Bridges, high-rise buildings, and precast concrete elements are among the structures that benefit significantly from the use of prestressed spiral rib wire.

9. Conclusion

Prestressed spiral rib wire represents a significant advancement in construction materials, offering numerous benefits including increased strength, cost-effectiveness, design flexibility, and enhanced safety. As the construction industry continues to evolve, adopting innovative solutions like prestressed spiral rib wire will be crucial for meeting the demands of modern infrastructure. Embracing these advancements not only fosters improved building practices but also promotes sustainability, making it an ideal choice for future construction projects.

Latest News

Why Choose Uncoated Prestressed Wire for Your Next Building Project?

Why Choose Uncoated Prestressed Wire for Your Next Building Project? Understanding Uncoated Prestressed Wire In the world of construction and architectural design, the materials you choose can significantly impact the overall success and longevity of a project. One material that stands out in the realm of concrete reinforcement is uncoated prestressed wire. This article delves into the advantages

2025-08-10

Understanding Uncoated Prestressed Wire: A Key Component in Construction

Uncoated prestressed wire is a crucial element in the construction and decorative materials sector, particularly in steel applications. This type of wire is designed to provide enhanced structural performance by being tensioned prior to the application of loads, thus improving the overall strength and durability of concrete structures. The primary advantage of uncoated prestressed wire lies in it

2025-08-07

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction In the dynamic world of construction, material choices can significantly influence project outcomes. Among the myriad of options available, uncoated prestressed wire has emerged as a pivotal component in modern engineering. In this comprehensive article, we will delve into the multifaceted benefits of uncoated prestressed w

2025-08-04

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture Introduction to Prestressed Reinforced Ribbed Wire Prestressed reinforced ribbed wire is a crucial material in the field of modern architecture and construction. It combines the advantages of prestressing technology with the physical properties of ribbed wire, enhancing the strength and durability of concrete structures.

2025-07-29

Understanding Prestressed Reinforced Ribbed Wire: A Key Component in Modern Construction

Prestressed reinforced ribbed wire is an innovative material widely used in the construction and decoration sectors, particularly within steel materials and wire ropes. This specialized wire combines the benefits of prestressing techniques with ribbed surface characteristics to provide superior strength, flexibility, and durability. Understanding the properties and applications of prestressed rein

2025-07-26

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction Table of Contents 1. Introduction to Prestressed Reinforced Ribbed Wire 2. What is Prestressed Reinforced Ribbed Wire? 3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire 3.1 Enhanced Strength and Load-Bearing Capacity 3.2 Durability and Longevity 3.3 Cost-Effective

2025-07-23