Why Choose Uncoated Prestressed Wire for Your Next Building Project?

Release time:

2025-08-10

Why Choose Uncoated Prestressed Wire for Your Next Building Project? Understanding Uncoated Prestressed Wire In the world of construction and architectural design, the materials you choose can significantly impact the overall success and longevity of a project. One material that stands out in the realm of concrete reinforcement is uncoated prestressed wire. This article delves into the advantages

Why Choose Uncoated Prestressed Wire for Your Next Building Project?

Understanding Uncoated Prestressed Wire

In the world of construction and architectural design, the materials you choose can significantly impact the overall success and longevity of a project. One material that stands out in the realm of concrete reinforcement is uncoated prestressed wire. This article delves into the advantages and applications of uncoated prestressed wire, demonstrating why it should be your go-to choice for your next building project.

What is Prestressed Wire?

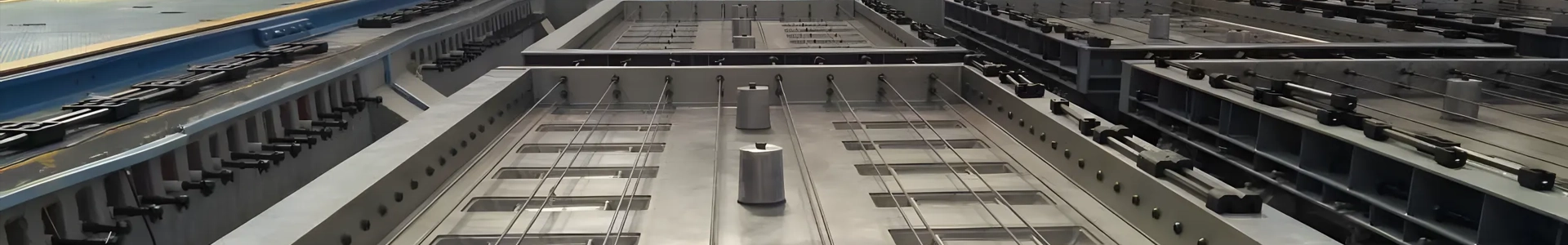

Prestressed wire is a high-strength steel wire that is specifically designed to withstand tensile forces. It is commonly used in prestressed concrete, where the wire is tensioned before the concrete is poured. This tension helps create a compressive force in the concrete, enhancing its load-bearing capabilities.

Composition and Characteristics

Uncoated prestressed wire is typically made from high-carbon steel, known for its exceptional tensile strength and durability. The absence of coating allows for better bonding with concrete, resulting in improved structural integrity. This wire is manufactured in various diameters and strengths, making it suitable for a wide range of applications.

Benefits of Using Uncoated Prestressed Wire

1. Enhanced Durability and Strength

One of the primary reasons to choose uncoated prestressed wire is its remarkable strength-to-weight ratio. The high tensile strength of this wire ensures that it can withstand substantial loads without deformation, making it ideal for heavy-duty applications.

2. Improved Bonding with Concrete

The uncoated surface of the wire allows for a superior bond with the surrounding concrete. This bond is crucial for the overall strength and durability of the structure, as it helps distribute loads evenly throughout the material.

3. Cost-Effectiveness

While the initial investment in uncoated prestressed wire may be slightly higher than that of coated alternatives, its long-term benefits often outweigh the costs. Reduced maintenance and repair needs due to its durability lead to overall savings over the lifespan of the project.

4. Versatility in Applications

Uncoated prestressed wire can be used in a variety of construction projects, including bridges, parking garages, and high-rise buildings. Its adaptability makes it a popular choice among engineers and architects who require reliable materials for diverse applications.

5. Resistance to Environmental Factors

Unlike coated wires, which may deteriorate over time, uncoated prestressed wire is less susceptible to environmental factors such as moisture and temperature fluctuations. This resistance is essential for constructions in varying climates, ensuring the longevity of the structure.

Applications of Uncoated Prestressed Wire

1. Bridges and Overpasses

In bridge construction, uncoated prestressed wire is commonly used to enhance load-bearing capacity. By incorporating this wire into the design, engineers can create safer and more durable structures that can withstand heavy traffic and environmental stressors.

2. High-Rise Buildings

For skyscrapers and high-rise buildings, the strength provided by uncoated prestressed wire is invaluable. It allows for the construction of slender, tall structures without compromising safety, making it a favored choice in urban development.

3. Parking Structures

Parking garages require robust materials to support the weight of vehicles and withstand daily wear and tear. The use of uncoated prestressed wire ensures that these structures remain safe and functional for years to come.

4. Industrial Applications

In industrial settings, uncoated prestressed wire is utilized in the construction of storage facilities, warehouses, and manufacturing plants. Its ability to bear heavy loads makes it an ideal choice for these demanding environments.

Installation and Best Practices

1. Proper Tensioning Techniques

To achieve optimal results, it is crucial to follow proper tensioning techniques during installation. This process involves applying the appropriate amount of tension to the wire before the concrete is poured, ensuring maximum strength and performance.

2. Quality Control Measures

Employing rigorous quality control measures during the manufacturing and installation of uncoated prestressed wire ensures that it meets the necessary standards for strength and durability. Regular inspections and testing are essential to maintaining the integrity of the structure.

Comparative Analysis: Uncoated vs. Coated Prestressed Wire

1. Performance

While both coated and uncoated prestressed wires serve similar purposes, uncoated wire often outperforms its coated counterpart in terms of bonding with concrete and resistance to environmental factors.

2. Cost Considerations

Although uncoated prestressed wire may have a higher upfront cost, its long-term performance and durability lead to lower maintenance and repair expenses. In contrast, coated wires may require more frequent replacements, increasing overall project costs.

3. Environmental Impact

Uncoated prestressed wire is often regarded as more environmentally friendly due to its lower reliance on coatings, which may involve harmful chemicals. This aspect is particularly important in today's eco-conscious construction industry.

FAQs about Uncoated Prestressed Wire

1. What makes uncoated prestressed wire a superior choice for construction?

Uncoated prestressed wire offers superior bonding with concrete, enhanced durability, and a high strength-to-weight ratio, making it ideal for various construction applications.

2. Can uncoated prestressed wire be used in all climates?

Yes, its resistance to environmental factors makes uncoated prestressed wire suitable for use in various climates, ensuring structural integrity over time.

3. How is uncoated prestressed wire installed?

Installation involves tensioning the wire before pouring concrete, ensuring optimal performance. Proper techniques and quality control are crucial during this process.

4. Is uncoated prestressed wire more expensive than coated options?

While the initial cost may be higher, uncoated prestressed wire often results in lower maintenance costs, making it a more cost-effective choice in the long run.

5. What types of projects benefit most from uncoated prestressed wire?

Uncoated prestressed wire is ideal for bridges, high-rise buildings, parking structures, and industrial applications, where strength and durability are paramount.

Conclusion

Choosing the right materials for your building project is essential for its success and longevity. Uncoated prestressed wire stands out as an exceptional choice, offering unparalleled strength, durability, and versatility. Its ability to bond effectively with concrete and resist environmental factors makes it a top contender in modern construction. By opting for uncoated prestressed wire, you ensure that your project not only meets but exceeds industry standards, ultimately leading to safer and more resilient structures.

Latest News

Why Choose Uncoated Prestressed Wire for Your Next Building Project?

Why Choose Uncoated Prestressed Wire for Your Next Building Project? Understanding Uncoated Prestressed Wire In the world of construction and architectural design, the materials you choose can significantly impact the overall success and longevity of a project. One material that stands out in the realm of concrete reinforcement is uncoated prestressed wire. This article delves into the advantages

2025-08-10

Understanding Uncoated Prestressed Wire: A Key Component in Construction

Uncoated prestressed wire is a crucial element in the construction and decorative materials sector, particularly in steel applications. This type of wire is designed to provide enhanced structural performance by being tensioned prior to the application of loads, thus improving the overall strength and durability of concrete structures. The primary advantage of uncoated prestressed wire lies in it

2025-08-07

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction In the dynamic world of construction, material choices can significantly influence project outcomes. Among the myriad of options available, uncoated prestressed wire has emerged as a pivotal component in modern engineering. In this comprehensive article, we will delve into the multifaceted benefits of uncoated prestressed w

2025-08-04

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture Introduction to Prestressed Reinforced Ribbed Wire Prestressed reinforced ribbed wire is a crucial material in the field of modern architecture and construction. It combines the advantages of prestressing technology with the physical properties of ribbed wire, enhancing the strength and durability of concrete structures.

2025-07-29

Understanding Prestressed Reinforced Ribbed Wire: A Key Component in Modern Construction

Prestressed reinforced ribbed wire is an innovative material widely used in the construction and decoration sectors, particularly within steel materials and wire ropes. This specialized wire combines the benefits of prestressing techniques with ribbed surface characteristics to provide superior strength, flexibility, and durability. Understanding the properties and applications of prestressed rein

2025-07-26

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction Table of Contents 1. Introduction to Prestressed Reinforced Ribbed Wire 2. What is Prestressed Reinforced Ribbed Wire? 3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire 3.1 Enhanced Strength and Load-Bearing Capacity 3.2 Durability and Longevity 3.3 Cost-Effective

2025-07-23