Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction

Release time:

2025-08-04

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction In the dynamic world of construction, material choices can significantly influence project outcomes. Among the myriad of options available, uncoated prestressed wire has emerged as a pivotal component in modern engineering. In this comprehensive article, we will delve into the multifaceted benefits of uncoated prestressed w

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction

In the dynamic world of construction, material choices can significantly influence project outcomes. Among the myriad of options available, uncoated prestressed wire has emerged as a pivotal component in modern engineering. In this comprehensive article, we will delve into the multifaceted benefits of uncoated prestressed wire, its applications, and its pivotal role in the construction industry.

Table of Contents

- Introduction to Uncoated Prestressed Wire

- What is Prestressed Wire?

- Advantages of Uncoated Prestressed Wire

- Applications of Uncoated Prestressed Wire in Construction

- Comparative Analysis with Coated Alternatives

- Design Considerations for Using Uncoated Prestressed Wire

- Environmental Impact of Uncoated Prestressed Wire

- Future Trends in Construction Materials

- Frequently Asked Questions

- Conclusion

Introduction to Uncoated Prestressed Wire

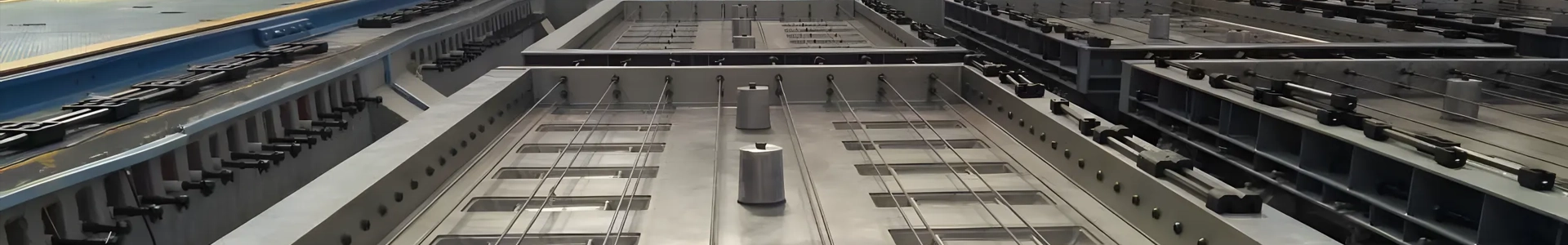

In contemporary construction, the quest for materials that offer both strength and flexibility is ongoing. Uncoated prestressed wire has emerged as a vital element in achieving structural resilience and efficiency. This type of wire, characterized by its high tensile strength and minimal elongation under load, is crucial for various applications, including bridges, high-rise buildings, and precast elements.

What is Prestressed Wire?

Prestressed wire is a high-strength steel wire specifically designed for prestressing concrete structures. The process involves subjecting the wire to a tensile force before the structural load is applied. This preloading creates a compressive force within the concrete, allowing it to withstand greater loads and reducing the risk of cracking. Uncoated prestressed wire, as the name suggests, lacks a protective coating, making it ideal for certain types of construction where bond strength is paramount.

Composition and Manufacturing of Uncoated Prestressed Wire

Uncoated prestressed wire is typically composed of high carbon steel, engineered to provide superior tensile strength and ductility. The manufacturing process includes drawing the wire through a series of dies, which enhances its mechanical properties. By eliminating the coating, manufacturers can offer a wire that adheres more effectively to concrete, resulting in improved structural performance.

Advantages of Uncoated Prestressed Wire

The utilization of uncoated prestressed wire offers several distinct advantages that contribute to more efficient construction practices and improved structural performance.

Enhanced Bonding Characteristics

One of the primary benefits of uncoated prestressed wire is its enhanced bonding characteristics. Without any coating, the wire forms a stronger bond with concrete, leading to better load transfer and increased overall stability. This attribute is critical in applications where safety and structural integrity are paramount.

Cost-Effectiveness

Uncoated prestressed wire is often more cost-effective than its coated counterparts. The absence of a protective layer reduces material costs while maintaining performance standards. This makes it an attractive option for large-scale construction projects where budget constraints are a significant concern.

Weight Efficiency

In construction, weight efficiency can lead to reduced material usage and lower transportation costs. Uncoated prestressed wire’s high strength-to-weight ratio allows engineers to use less material while achieving greater load-bearing capacity. This efficiency translates to less material waste and a lighter overall structure.

Environmental Benefits

With increasing awareness of environmental responsibility, the choice of building materials has a notable impact on sustainability. Uncoated prestressed wire contributes to greener construction practices by minimizing waste and reducing the need for chemical coatings, which can have environmental repercussions.

Applications of Uncoated Prestressed Wire in Construction

The versatility of uncoated prestressed wire makes it suitable for a variety of construction applications. Understanding where and how this material can be utilized enhances its value proposition in modern construction.

Bridges and Overpasses

Uncoated prestressed wire is frequently used in the construction of bridges and overpasses, where it provides the necessary tensile strength to withstand heavy loads and dynamic forces. Its ability to maintain structural integrity over time is crucial in these high-stress environments.

High-Rise Buildings

In high-rise construction, the challenges of vertical load-bearing are significant. Uncoated prestressed wire contributes to the structural framework, allowing for taller buildings without compromising safety. Its lightweight nature reduces the overall load on the foundation.

Precast Concrete Elements

Uncoated prestressed wire plays a pivotal role in the manufacturing of precast concrete components such as walls, floors, and beams. The enhanced bond between the wire and concrete ensures durability and longevity, essential for prefabricated elements.

Water Retaining Structures

Structures designed to retain water, such as reservoirs and water tanks, benefit immensely from uncoated prestressed wire. Its resistance to cracking under pressure ensures the integrity of these vital structures, preventing leaks and structural failures.

Comparative Analysis with Coated Alternatives

While uncoated prestressed wire has distinct advantages, it is essential to compare it with coated alternatives to understand its unique position in the market.

Performance Comparison

Coated prestressed wires often provide better corrosion resistance, making them suitable for certain environments. However, uncoated wires offer superior bonding properties, which can outweigh the benefits of coatings in many applications. This trade-off is crucial when selecting the appropriate material for specific projects.

Long-Term Durability

While coated wires may resist environmental factors longer in corrosive settings, uncoated prestressed wires have proven their durability in various applications. Their performance under high stress and load makes them reliable for long-term use.

Design Considerations for Using Uncoated Prestressed Wire

When integrating uncoated prestressed wire into construction designs, several considerations must be taken into account to maximize its benefits.

Load Requirements

Understanding the load requirements of a project is critical. Engineers must calculate the precise tensile strength needed to ensure that the uncoated wire can handle the expected loads without compromising safety.

Environmental Conditions

The environmental conditions surrounding a construction site can influence the decision to use uncoated prestressed wire. Areas prone to severe corrosion may necessitate additional protective measures to ensure longevity.

Compliance with Standards

Compliance with building codes and standards is non-negotiable. Engineers must ensure that all materials, including uncoated prestressed wire, meet the relevant specifications to ensure safety and reliability.

Environmental Impact of Uncoated Prestressed Wire

In an era of heightened environmental awareness, the impact of construction materials on the ecosystem is a vital consideration. Uncoated prestressed wire offers several benefits in this regard.

Reduced Chemical Use

Without the need for coatings, uncoated prestressed wire minimizes the use of harmful chemicals often associated with protective coatings. This reduction contributes to a healthier environment both during production and throughout its lifecycle.

Recyclability

Steel is one of the most recyclable materials available. Uncoated prestressed wire can be recycled at the end of its lifespan, reducing waste and supporting sustainable construction practices.

Future Trends in Construction Materials

The construction industry is continuously evolving, with innovations paving the way for more efficient and sustainable practices. Uncoated prestressed wire is likely to play a prominent role in future trends.

Advancements in Material Science

As material science advances, we can expect improvements in the properties of uncoated prestressed wire. Enhanced strength, ductility, and resistance to environmental factors will ensure its relevance in modern construction.

Integration with Smart Technologies

The future of construction lies in smart technologies. Integrating uncoated prestressed wire with sensors and monitoring systems can provide real-time data on structural performance, enhancing safety and maintenance practices.

Frequently Asked Questions

1. What is the primary difference between coated and uncoated prestressed wire?

The primary difference lies in the bonding characteristics and corrosion resistance. Uncoated prestressed wire offers better bonding with concrete, while coated wire typically provides enhanced corrosion resistance.

2. In what environments is uncoated prestressed wire most effective?

Uncoated prestressed wire is most effective in environments where bonding strength is crucial and where corrosion risks are minimal or can be managed through design.

3. How does uncoated prestressed wire contribute to sustainability in construction?

Uncoated prestressed wire contributes to sustainability by minimizing chemical use, reducing waste, and being fully recyclable at the end of its lifecycle.

4. What are the challenges of using uncoated prestressed wire?

Challenges include potential corrosion in aggressive environments and ensuring compliance with building codes and standards to guarantee safety and reliability.

5. Can uncoated prestressed wire be used in seismic zones?

Yes, uncoated prestressed wire can be effectively used in seismic zones, provided that the design accounts for dynamic loads and the necessary safety factors.

Conclusion

Uncoated prestressed wire stands out in the construction industry for its unique properties, including enhanced bonding, cost-effectiveness, and environmental benefits. As we continue to push the boundaries of engineering and construction practices, this material proves indispensable in achieving resilient and sustainable structures. By understanding its advantages and applications, we can make informed decisions that not only enhance the integrity of our projects but also contribute positively to the environment. In embracing uncoated prestressed wire, we are not just building structures; we are laying the foundation for a smarter and greener future in construction.

Latest News

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction In the dynamic world of construction, material choices can significantly influence project outcomes. Among the myriad of options available, uncoated prestressed wire has emerged as a pivotal component in modern engineering. In this comprehensive article, we will delve into the multifaceted benefits of uncoated prestressed w

2025-08-04

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture Introduction to Prestressed Reinforced Ribbed Wire Prestressed reinforced ribbed wire is a crucial material in the field of modern architecture and construction. It combines the advantages of prestressing technology with the physical properties of ribbed wire, enhancing the strength and durability of concrete structures.

2025-07-29

Understanding Prestressed Reinforced Ribbed Wire: A Key Component in Modern Construction

Prestressed reinforced ribbed wire is an innovative material widely used in the construction and decoration sectors, particularly within steel materials and wire ropes. This specialized wire combines the benefits of prestressing techniques with ribbed surface characteristics to provide superior strength, flexibility, and durability. Understanding the properties and applications of prestressed rein

2025-07-26

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction Table of Contents 1. Introduction to Prestressed Reinforced Ribbed Wire 2. What is Prestressed Reinforced Ribbed Wire? 3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire 3.1 Enhanced Strength and Load-Bearing Capacity 3.2 Durability and Longevity 3.3 Cost-Effective

2025-07-23

Understanding High-Tensile Indented PC Wire: A Key Material in Construction

High-tensile indented PC wire, short for prestressed concrete wire, is an innovative steel material that has gained significant attention in the construction industry due to its excellent strength-to-weight ratio and durability. This wire is manufactured with indents on its surface, which enhances its bond with concrete, making it an ideal choice for various structural applications. One of the sta

2025-07-20

High-Tensile Indented PC Wire: The Backbone of Earthquake-Resistant Structures

High-Tensile Indented PC Wire: Essential for Earthquake-Resistant Structures Table of Contents 1. Introduction to High-Tensile Indented PC Wire 2. Properties of High-Tensile Indented PC Wire 3. Benefits of Using High-Tensile Indented PC Wire in Construction 4. Applications of High-Tensile Indented PC Wire in Earthquake-Resistant Structures 5. Comparative Analysis: High-Tensile

2025-07-17