Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction

Release time:

2025-07-23

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction Table of Contents 1. Introduction to Prestressed Reinforced Ribbed Wire 2. What is Prestressed Reinforced Ribbed Wire? 3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire 3.1 Enhanced Strength and Load-Bearing Capacity 3.2 Durability and Longevity 3.3 Cost-Effective

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction

Table of Contents

- 1. Introduction to Prestressed Reinforced Ribbed Wire

- 2. What is Prestressed Reinforced Ribbed Wire?

- 3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire

- 3.1 Enhanced Strength and Load-Bearing Capacity

- 3.2 Durability and Longevity

- 3.3 Cost-Effectiveness in Construction Projects

- 3.4 Environmental Sustainability

- 3.5 Design Flexibility and Versatility

- 4. Applications of Prestressed Reinforced Ribbed Wire in Construction

- 5. Installation Process of Prestressed Reinforced Ribbed Wire

- 6. Maintenance and Care for Prestressed Reinforced Ribbed Wire Structures

- 7. Frequently Asked Questions

- 8. Conclusion

1. Introduction to Prestressed Reinforced Ribbed Wire

In the ever-evolving landscape of construction materials, prestressed reinforced ribbed wire has emerged as a game-changer. This innovative material bridges the gap between traditional reinforcement techniques and modern engineering needs, offering a plethora of benefits that cater to both structural integrity and economic efficiency. Understanding how prestressed reinforced ribbed wire functions and the advantages it brings can significantly impact construction outcomes.

2. What is Prestressed Reinforced Ribbed Wire?

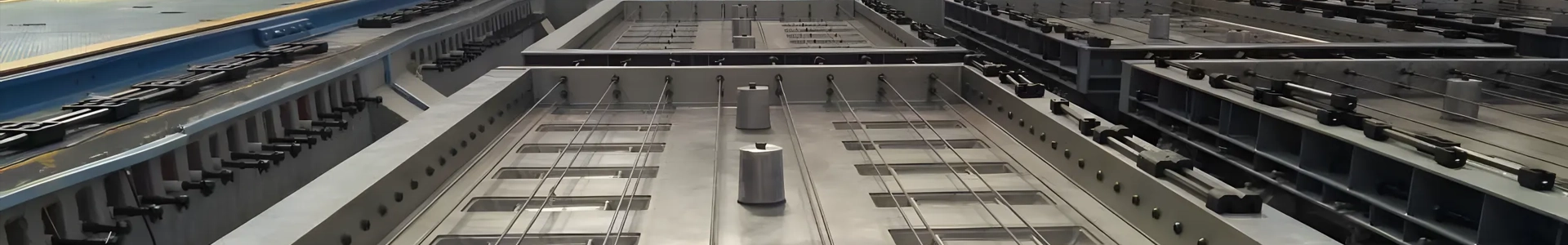

Prestressed reinforced ribbed wire is a type of tensioned steel wire typically used in reinforced concrete applications. Unlike standard reinforcement bars, prestressed wire is subjected to a process that puts it under tension before it is embedded within concrete. This tensioning process enhances the wire's ability to withstand tensile forces, making it an ideal choice for structures that require high strength and durability.

The ribbing on the wire surface serves to improve the bond between the wire and the concrete, ensuring a more effective load transfer during operation. This design feature not only enhances the overall strength of the construction but also contributes to the longevity of the structures built with this material.

3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire

Prestressed reinforced ribbed wire offers numerous benefits that make it a preferred choice in modern construction projects.

3.1 Enhanced Strength and Load-Bearing Capacity

One of the most significant advantages of prestressed reinforced ribbed wire is its enhanced strength. The tensioning process allows the wire to counteract compressive forces effectively, increasing the load-bearing capacity of concrete structures. This characteristic enables engineers to design slimmer and lighter structures without compromising on safety or durability.

3.2 Durability and Longevity

Structures built with prestressed reinforced ribbed wire are inherently more durable. The material exhibits superior resistance to fatigue and environmental factors, such as corrosion and extreme weather conditions. This durability translates into longer service life for buildings and infrastructure, reducing the need for frequent repairs and replacements.

3.3 Cost-Effectiveness in Construction Projects

While the initial cost of prestressed reinforced ribbed wire may be higher than traditional reinforcement materials, the long-term savings are substantial. The reduced need for maintenance, along with the ability to construct lighter and more efficient structures, leads to lower overall project costs. Additionally, the speed of installation can further cut labor costs, making it a financially viable option for contractors.

3.4 Environmental Sustainability

In today’s eco-conscious climate, the sustainability of construction materials is paramount. Prestressed reinforced ribbed wire contributes to sustainable building practices by allowing for the use of less concrete and steel in construction. This reduction in material usage not only minimizes waste but also lowers the carbon footprint of construction projects.

3.5 Design Flexibility and Versatility

Prestressed reinforced ribbed wire offers architects and engineers unparalleled design flexibility. It can be customized to meet specific project requirements and is suitable for a wide array of applications, from residential buildings to large-scale bridges. The adaptability of this material allows for innovative designs that are both aesthetically pleasing and structurally sound.

4. Applications of Prestressed Reinforced Ribbed Wire in Construction

The versatility of prestressed reinforced ribbed wire makes it ideal for a variety of construction applications, including:

- **High-rise Buildings**: Its strength and load-bearing capacity enable the construction of tall structures with minimal material use.

- **Bridges**: The material's resistance to bending and deflection makes it a favorite for bridge construction, ensuring long-term stability and safety.

- **Parking Structures**: Prestressed wire can support the heavy loads of vehicles while allowing for open and flexible design spaces.

- **Industrial Facilities**: Factories and warehouses benefit from the durability and cost-effectiveness of prestressed reinforced ribbed wire in their construction.

5. Installation Process of Prestressed Reinforced Ribbed Wire

The installation of prestressed reinforced ribbed wire requires careful planning and execution. The process typically involves several key steps:

1. **Design and Planning**: Engineers design the structure while taking into account the specific properties of the prestressed wire.

2. **Preparation**: The site is prepared, and concrete forms are set up.

3. **Tensioning**: The wire is tensioned using hydraulic jacks before it is embedded in concrete. This step is critical to ensuring the material fulfills its intended purpose.

4. **Concrete Pouring**: Once the wire is in place, concrete is poured, encasing the wire and allowing it to bond effectively.

5. **Curing**: The concrete is allowed to cure, enabling it to achieve its full strength.

6. **Final Inspection**: After curing, the structure undergoes inspection to ensure compliance with design specifications.

6. Maintenance and Care for Prestressed Reinforced Ribbed Wire Structures

While prestressed reinforced ribbed wire structures are designed for longevity, routine maintenance is essential for ensuring their continued performance. Key maintenance practices include:

- **Regular Inspections**: Checking for any signs of wear, corrosion, or structural damage.

- **Cleaning**: Ensuring that the surfaces remain clean and free from debris that could trap moisture and lead to corrosion.

- **Repairs**: Addressing any potential issues immediately to prevent further damage.

Implementing a proactive maintenance plan will extend the lifespan of structures built with prestressed reinforced ribbed wire and ensure safety.

7. Frequently Asked Questions

- What is the main advantage of prestressed reinforced ribbed wire over traditional reinforcement?

The main advantage is its enhanced strength and load-bearing capacity, which allows for slimmer designs and greater structural efficiency. - Is prestressed reinforced ribbed wire more cost-effective in the long run?

Yes, despite higher initial costs, its durability and reduced maintenance needs lead to lower lifetime costs. - Can prestressed reinforced ribbed wire be used in residential construction?

Absolutely! It is suitable for various applications, including residential buildings, due to its strength and versatility. - How does prestressing affect the concrete curing process?

The tensioning of the wire must be carefully timed with the concrete pouring and curing to ensure optimal bonding and strength development. - What environmental benefits does prestressed reinforced ribbed wire offer?

It reduces material usage and waste, lowering the overall carbon footprint of construction projects.

8. Conclusion

Prestressed reinforced ribbed wire stands as a remarkable advancement in construction materials, offering unparalleled benefits that enhance structural integrity, durability, and cost-effectiveness. As the construction industry continues to evolve, embracing innovative materials like prestressed reinforced ribbed wire will play a crucial role in shaping the future of building practices. By understanding its advantages and applications, architects, engineers, and contractors can harness the full potential of this material, leading to safer, more efficient, and sustainable structures.

Latest News

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction Table of Contents 1. Introduction to Prestressed Reinforced Ribbed Wire 2. What is Prestressed Reinforced Ribbed Wire? 3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire 3.1 Enhanced Strength and Load-Bearing Capacity 3.2 Durability and Longevity 3.3 Cost-Effective

2025-07-23

Understanding High-Tensile Indented PC Wire: A Key Material in Construction

High-tensile indented PC wire, short for prestressed concrete wire, is an innovative steel material that has gained significant attention in the construction industry due to its excellent strength-to-weight ratio and durability. This wire is manufactured with indents on its surface, which enhances its bond with concrete, making it an ideal choice for various structural applications. One of the sta

2025-07-20

High-Tensile Indented PC Wire: The Backbone of Earthquake-Resistant Structures

High-Tensile Indented PC Wire: Essential for Earthquake-Resistant Structures Table of Contents 1. Introduction to High-Tensile Indented PC Wire 2. Properties of High-Tensile Indented PC Wire 3. Benefits of Using High-Tensile Indented PC Wire in Construction 4. Applications of High-Tensile Indented PC Wire in Earthquake-Resistant Structures 5. Comparative Analysis: High-Tensile

2025-07-17

Understanding High-Tensile Indented PC Wire: Strength and Versatility in Construction

High-tensile indented PC wire, or prestressed concrete wire, is engineered to provide exceptional strength and flexibility, making it a vital material in various construction applications. The term "high-tensile" refers to the wire’s ability to withstand significant tensile forces without breaking, ensuring its reliability in structural applications. The "indented" feature enhances its adhesion pr

2025-07-14

Understanding Prestressed Spiral Rib Wire: A Comprehensive Overview for Professionals

--- Prestressed spiral rib wire is an advanced type of steel wire, essential in the construction and decoration sectors, particularly within the realm of prestressed concrete. This specialized wire is designed to enhance the load-bearing capacity and overall performance of concrete structures. Its unique spiral rib design allows for better bonding with concrete, ensuring that the wire effectively

2025-07-08

Why Choose Prestressed Spiral Rib Wire for Your Building Projects?

Why Choose Prestressed Spiral Rib Wire for Your Building Projects? Table of Contents Introduction to Prestressed Spiral Rib Wire Benefits of Using Prestressed Spiral Rib Wire High Strength and Durability Enhanced Flexibility and Adaptability Cost Efficiency and Long-Term Savings Applications of Prestressed Spiral Rib Wire

2025-07-05