Why Choose Prestressed Spiral Rib Wire for Your Building Projects?

Release time:

2025-07-05

Why Choose Prestressed Spiral Rib Wire for Your Building Projects? Table of Contents Introduction to Prestressed Spiral Rib Wire Benefits of Using Prestressed Spiral Rib Wire High Strength and Durability Enhanced Flexibility and Adaptability Cost Efficiency and Long-Term Savings Applications of Prestressed Spiral Rib Wire

Why Choose Prestressed Spiral Rib Wire for Your Building Projects?

Table of Contents

- Introduction to Prestressed Spiral Rib Wire

- Benefits of Using Prestressed Spiral Rib Wire

- High Strength and Durability

- Enhanced Flexibility and Adaptability

- Cost Efficiency and Long-Term Savings

- Applications of Prestressed Spiral Rib Wire

- Installation Guidelines for Prestressed Spiral Rib Wire

- Safety Considerations in Using Prestressed Spiral Rib Wire

- Comparing Prestressed Spiral Rib Wire with Other Materials

- Frequently Asked Questions

- Conclusion

Introduction to Prestressed Spiral Rib Wire

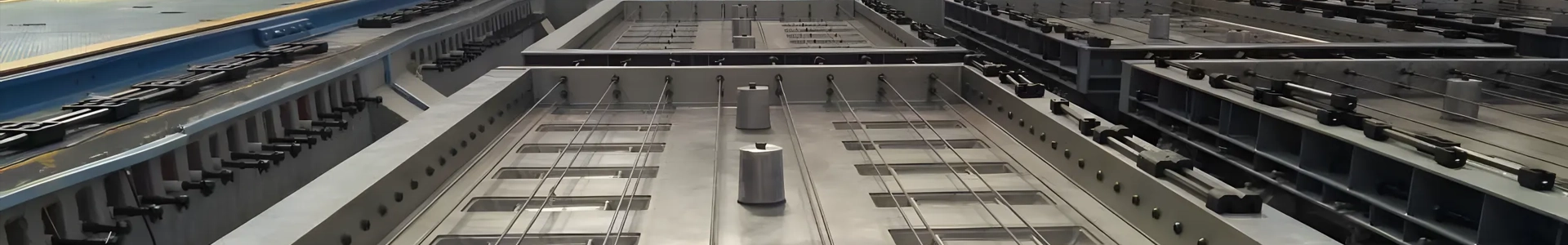

In the realm of construction materials, **prestressed spiral rib wire** has emerged as a game-changer. This innovative type of wire is designed specifically for enhancing the durability and strength of structures. By utilizing pretensioning techniques, the wire can withstand significant tensile forces, making it ideal for various building projects.

In this article, we will delve into the numerous benefits of prestressed spiral rib wire, its applications, and why it is increasingly becoming the material of choice for civil engineers and contractors alike.

Benefits of Using Prestressed Spiral Rib Wire

Understanding the advantages of prestressed spiral rib wire can greatly influence its selection for building projects.

High Strength and Durability

One of the standout features of prestressed spiral rib wire is its **high strength-to-weight ratio**. This characteristic allows for the creation of lighter structures without compromising on integrity. **Durability** is also a key trait; the wire is resistant to corrosion and fatigue, ensuring that it maintains its performance over time, even in harsh environments.

Enhanced Flexibility and Adaptability

Prestressed spiral rib wire is designed to be flexible, allowing it to adapt to various structural requirements. This flexibility makes it suitable for different architectural designs and load-bearing needs. Whether you are constructing a bridge, a high-rise building, or residential homes, this wire can easily accommodate diverse engineering demands.

Cost Efficiency and Long-Term Savings

While the initial investment in prestressed spiral rib wire may be higher than traditional options, the long-term savings are significant. The wire’s durability leads to less frequent repairs and replacements, while its strength allows for reduced material use in construction. This combination results in **lower lifecycle costs**, making it an economically sound choice for construction projects.

Applications of Prestressed Spiral Rib Wire

Prestressed spiral rib wire is versatile and can be employed in various applications across the construction industry.

Construction and Structural Reinforcement

The primary application of prestressed spiral rib wire is in the reinforcement of concrete structures. It is commonly used in:

- **Bridges**: Providing necessary support while minimizing weight.

- **High-rise buildings**: Enhancing stability and load distribution.

- **Foundations**: Increasing strength to withstand soil pressure.

Specialty Applications

Beyond conventional construction, prestressed spiral rib wire is also utilized in specialty applications, including:

- **Tensioned membranes**: Used in modern architectural designs for aesthetic appeal.

- **Post-tensioned slabs**: Offering flexibility in design and reducing the amount of concrete required.

- **Seismic retrofitting**: Improving the resilience of structures in earthquake-prone areas.

Installation Guidelines for Prestressed Spiral Rib Wire

Proper installation of prestressed spiral rib wire is critical to harnessing its benefits. Here are the key steps:

1. **Preparation**: Ensure that all materials and tools are available. Assess the site for any potential challenges.

2. **Placement**: Position the wire according to engineering specifications. It must be installed correctly to maintain the structural integrity of the project.

3. **Tensioning**: Apply the required tension to the wire, ensuring uniform distribution throughout the structure.

4. **Inspection**: Conduct a thorough inspection before proceeding with the concrete pour to ensure proper alignment and tension.

Adhering to these guidelines will maximize the performance and longevity of the prestressed spiral rib wire in your project.

Safety Considerations in Using Prestressed Spiral Rib Wire

Safety should always be a priority when working with construction materials. Here are some considerations:

- **Personal Protective Equipment (PPE)**: Ensure that all workers are equipped with appropriate PPE, including gloves, helmets, and eye protection.

- **Handling**: Take care when handling the wire as it is under tension. Improper handling can lead to accidents.

- **Training**: Workers should be trained in the proper techniques for installation and tensioning to avoid injuries.

Adhering to these safety protocols protects both workers and the integrity of the project.

Comparing Prestressed Spiral Rib Wire with Other Materials

When choosing materials for construction, it is essential to compare options. Here’s a quick comparison between prestressed spiral rib wire and other common materials:

- **Traditional Steel Reinforcement**: While traditional steel offers strength, it lacks the flexibility and adaptability of prestressed spiral rib wire. The latter often requires less material for the same strength.

- **Fiber-Reinforced Polymers (FRP)**: Although FRP materials are lightweight and resistant to corrosion, they do not provide the same level of tensile strength as prestressed spiral rib wire.

Ultimately, prestressed spiral rib wire combines the best attributes of strength, flexibility, and cost-effectiveness, making it a superior choice for modern construction.

Frequently Asked Questions

1. What is prestressed spiral rib wire?

Prestressed spiral rib wire is a type of wire designed for high-strength applications in construction. It is used to reinforce concrete structures by providing tensile support.

2. How does prestressed spiral rib wire improve construction efficiency?

Its high strength-to-weight ratio allows for lighter structures, reduced material requirements, and less frequent repairs, leading to overall cost savings and efficiency in construction.

3. In what types of projects is prestressed spiral rib wire most commonly used?

It is commonly used in bridges, high-rise buildings, foundations, and specialty applications like tensioned membranes and seismic retrofitting.

4. Are there any safety concerns associated with using prestressed spiral rib wire?

Yes, proper handling and installation are crucial. Workers should wear PPE and be trained to handle the wire safely to avoid accidents.

5. How does prestressed spiral rib wire compare to traditional steel reinforcement?

Prestressed spiral rib wire offers superior flexibility and adaptability, allowing for lighter structures and potentially lower material costs compared to traditional steel reinforcement.

Conclusion

Choosing the right materials for your building projects is crucial for ensuring safety, durability, and cost-effectiveness. **Prestressed spiral rib wire** emerges as an outstanding option, offering numerous benefits such as high strength, flexibility, and long-term savings. By understanding its advantages and applications, along with adhering to proper installation and safety protocols, you can make informed decisions that will enhance the quality and longevity of your constructions. With the construction industry continually evolving, adopting innovative materials like prestressed spiral rib wire may just be the key to staying ahead.

Latest News

Understanding Prestressed Spiral Rib Wire: A Comprehensive Overview for Professionals

--- Prestressed spiral rib wire is an advanced type of steel wire, essential in the construction and decoration sectors, particularly within the realm of prestressed concrete. This specialized wire is designed to enhance the load-bearing capacity and overall performance of concrete structures. Its unique spiral rib design allows for better bonding with concrete, ensuring that the wire effectively

2025-07-08

Why Choose Prestressed Spiral Rib Wire for Your Building Projects?

Why Choose Prestressed Spiral Rib Wire for Your Building Projects? Table of Contents Introduction to Prestressed Spiral Rib Wire Benefits of Using Prestressed Spiral Rib Wire High Strength and Durability Enhanced Flexibility and Adaptability Cost Efficiency and Long-Term Savings Applications of Prestressed Spiral Rib Wire

2025-07-05

Understanding Prestressed Spiral Rib Wire: A Key Component in Modern Construction

Prestressed spiral rib wire is a specialized type of steel wire that plays a significant role in modern construction and engineering projects. This material is designed to enhance the overall structural integrity of concrete elements, making it a vital component in various applications, particularly in prestressed concrete. The unique spiral rib design of the wire provides additional surface area

2025-07-02

Exploring the Benefits of Prestressed Spiral Rib Wire in Construction

Exploring the Benefits of Prestressed Spiral Rib Wire in Construction Table of Contents 1. Introduction to Prestressed Spiral Rib Wire 2. What is Prestressed Spiral Rib Wire? 3. Advantages of Using Prestressed Spiral Rib Wire 3.1 Increased Strength and Durability 3.2 Cost-Effectiveness 3.3 Design Flexibility 3.4 Reduced Construc

2025-06-29

Understanding Grooved Prestressed PC Wire: An Essential Component in Modern Construction

Grooved prestressed PC wire, or prestressed concrete wire, plays a pivotal role in the construction and building materials sector, particularly within the realm of steel materials. This specialized wire is designed to withstand high tensile loads and is commonly used in the production of prestressed concrete elements. The grooved design of this wire enhances its bonding with concrete, improving th

2025-06-26

Why Grooved Prestressed PC Wire is Essential for Modern Building Projects

Understanding Grooved Prestressed PC Wire: The Backbone of Modern Construction When it comes to modern building projects, **grooved prestressed PC wire** stands out as an essential component. This innovative material, designed specifically for high-performance applications, helps engineers and builders achieve optimal structural integrity and durability. In this article, we will explore the multif

2025-06-23