Why Grooved Prestressed PC Wire is Essential for Modern Building Projects

Release time:

2025-06-23

Understanding Grooved Prestressed PC Wire: The Backbone of Modern Construction When it comes to modern building projects, **grooved prestressed PC wire** stands out as an essential component. This innovative material, designed specifically for high-performance applications, helps engineers and builders achieve optimal structural integrity and durability. In this article, we will explore the multif

Understanding Grooved Prestressed PC Wire: The Backbone of Modern Construction

When it comes to modern building projects, **grooved prestressed PC wire** stands out as an essential component. This innovative material, designed specifically for high-performance applications, helps engineers and builders achieve optimal structural integrity and durability. In this article, we will explore the multifaceted advantages of using grooved prestressed PC wire, how it revolutionizes building practices, and why it is increasingly becoming the go-to choice for modern construction projects.

What is Grooved Prestressed PC Wire?

Grooved prestressed PC wire is a type of high-strength steel wire that is primarily used in prestressed concrete applications. Unlike traditional wire, grooved wire features a unique ribbed design that enhances its grip within concrete, allowing for better load distribution and improved tensile strength. This innovation contributes to its widespread use in various construction scenarios, including bridges, high-rise buildings, and parking structures.

The Advantages of Using Grooved Prestressed PC Wire

Understanding the advantages of grooved prestressed PC wire is crucial for anyone involved in construction or architectural design. Here’s a detailed look at why this material is favored in today’s construction landscape.

1. Enhanced Load-Bearing Capacity

One of the primary benefits of grooved prestressed PC wire is its **enhanced load-bearing capacity**. The grooves on the wire create a mechanical interlock with the concrete, allowing for superior transfer of stresses. This feature makes structures more resilient, enabling them to withstand heavy loads without compromising safety.

2. Improved Durability and Longevity

Grooved prestressed PC wire exhibits remarkable durability, largely due to its high-strength steel composition. Structures reinforced with this type of wire can endure harsh weather conditions, including extreme temperatures, humidity, and corrosive environments. This durability translates into longer service life and reduced maintenance costs, making it a cost-effective solution for builders.

3. Flexibility in Design

Modern architecture often demands innovative and flexible design solutions. Grooved prestressed PC wire allows for **greater design freedom** compared to traditional reinforcement methods. Engineers can create thinner slabs and longer spans while maintaining structural integrity, which can lead to more aesthetically pleasing and functional designs.

4. Enhanced Safety Features

Safety is paramount in construction, and grooved prestressed PC wire contributes significantly to this aspect. The superior grip and load distribution provided by the grooves minimize the risk of structural failure. Additionally, the use of this wire can help meet stringent safety codes and regulations, ensuring that buildings are constructed to withstand various forces and conditions.

4.1 Reducing Structural Failures

Statistical data shows that structures reinforced with grooved prestressed PC wire exhibit lower rates of structural failures. This fact is especially relevant in seismic zones, where the ability to absorb and dissipate energy is vital.

5. Cost-Effectiveness

While the initial investment in grooved prestressed PC wire might be higher compared to traditional materials, the long-term savings are substantial. With reduced maintenance costs and the extended lifespan of structures, builders and developers can realize significant financial benefits over time.

Applications of Grooved Prestressed PC Wire in Modern Construction

Grooved prestressed PC wire is versatile, finding applications in a variety of construction projects. Here, we’ll explore some of the prominent uses of this material.

1. High-Rise Buildings

In high-rise construction, the need for strong, lightweight materials is critical. Grooved prestressed PC wire provides the necessary tensile strength while allowing for thinner slabs and reduced weight, which can streamline the overall building process.

2. Bridges and Overpasses

The transportation infrastructure often relies on prestressed concrete to ensure safety and longevity. Grooved prestressed PC wire is widely used in bridges and overpasses, where the ability to handle dynamic loads is essential.

3. Parking Structures

Parking structures must be able to withstand the weight of vehicles while also providing long spans for accessibility. The unique properties of grooved prestressed PC wire make it an ideal choice for these applications, ensuring that structures are both safe and cost-effective.

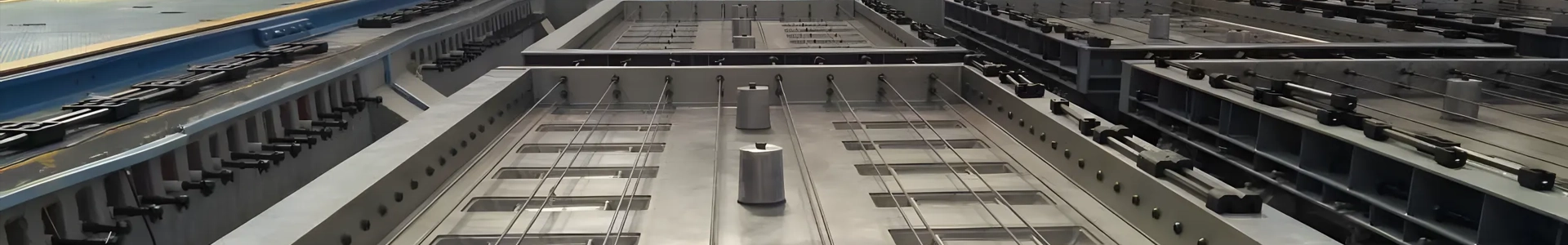

How Grooved Prestressed PC Wire is Manufactured

Understanding the manufacturing process of grooved prestressed PC wire can provide insights into its effectiveness and reliability.

1. Material Selection

The manufacturing process begins with selecting high-quality steel. This material is chosen for its strength and resistance to deformation.

2. Wire Drawing

The steel is then drawn into wire, reducing its diameter to the desired specifications. This process enhances the wire's tensile strength, making it more suitable for prestressing applications.

3. Grooving Process

Once the wire is drawn to size, it undergoes a grooving process that creates the distinctive ribbed pattern. This pattern is critical for ensuring the wire’s grip within concrete.

4. Quality Control

Finally, rigorous quality control checks ensure that the grooved prestressed PC wire meets industry standards for strength and durability. This step is essential for maintaining the reliability of the material in construction.

Comparing Grooved Prestressed PC Wire with Other Reinforcement Methods

While grooved prestressed PC wire offers numerous advantages, it is essential to compare it with other reinforcement methods to understand its unique benefits better.

1. Traditional Reinforcement Bars (Rebar)

Traditional rebar is a common choice for reinforcing concrete. However, it lacks the load distribution capabilities of grooved prestressed wire. Rebar can also suffer from corrosion over time, while grooved wire offers enhanced durability.

2. Fiber Reinforcement

Fiber reinforcement is gaining popularity, particularly for small-scale projects. However, for large structures requiring significant load-bearing capacity, grooved prestressed PC wire is the superior option. Its ability to handle dynamic forces makes it ideal for critical applications.

The Future of Grooved Prestressed PC Wire in Construction

As technology advances, the future of grooved prestressed PC wire looks promising. Innovations in material science and manufacturing processes are likely to yield even stronger and more efficient wire types.

1. Sustainable Manufacturing Practices

The construction industry is increasingly focusing on sustainability. Future manufacturing practices for grooved prestressed PC wire may incorporate recycled materials, reducing environmental impact while maintaining performance standards.

2. Integration with Smart Technology

The incorporation of smart technology into construction materials is on the rise. Grooved prestressed PC wire could potentially be integrated with sensors to monitor strain and other conditions in real time, enhancing safety and performance.

Frequently Asked Questions (FAQs)

1. What is the primary advantage of using grooved prestressed PC wire?

The primary advantage is its enhanced load-bearing capacity, which provides superior tensile strength and durability in construction.

2. How does grooved prestressed PC wire compare to traditional reinforcement methods?

Grooved prestressed PC wire offers better load distribution and durability compared to traditional rebar and fiber reinforcement, making it ideal for high-demand applications.

3. Is grooved prestressed PC wire cost-effective?

Yes, while the initial investment may be higher, the long-term savings from reduced maintenance costs and increased lifespan make it a cost-effective choice.

4. Can grooved prestressed PC wire be used in seismic zones?

Absolutely! Grooved prestressed PC wire is designed to handle dynamic loads, making it suitable for construction in seismic zones.

5. What is the manufacturing process for grooved prestressed PC wire?

The process involves material selection, wire drawing, grooving, and rigorous quality control to ensure strength and durability.

Conclusion

In conclusion, grooved prestressed PC wire is an indispensable material in modern construction, offering numerous advantages such as enhanced load-bearing capacity, durability, and design flexibility. Its applications in high-rise buildings, bridges, and parking structures demonstrate its versatility and effectiveness. As the construction industry continues to evolve, the future of grooved prestressed PC wire looks bright, with advancements in sustainability and smart technology on the horizon. Embracing this innovative material is essential for any builder or engineer seeking to elevate their projects to new heights.

Latest News

Why Choose Uncoated Prestressed Wire for Your Next Building Project?

Why Choose Uncoated Prestressed Wire for Your Next Building Project? Understanding Uncoated Prestressed Wire In the world of construction and architectural design, the materials you choose can significantly impact the overall success and longevity of a project. One material that stands out in the realm of concrete reinforcement is uncoated prestressed wire. This article delves into the advantages

2025-08-10

Understanding Uncoated Prestressed Wire: A Key Component in Construction

Uncoated prestressed wire is a crucial element in the construction and decorative materials sector, particularly in steel applications. This type of wire is designed to provide enhanced structural performance by being tensioned prior to the application of loads, thus improving the overall strength and durability of concrete structures. The primary advantage of uncoated prestressed wire lies in it

2025-08-07

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction In the dynamic world of construction, material choices can significantly influence project outcomes. Among the myriad of options available, uncoated prestressed wire has emerged as a pivotal component in modern engineering. In this comprehensive article, we will delve into the multifaceted benefits of uncoated prestressed w

2025-08-04

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture Introduction to Prestressed Reinforced Ribbed Wire Prestressed reinforced ribbed wire is a crucial material in the field of modern architecture and construction. It combines the advantages of prestressing technology with the physical properties of ribbed wire, enhancing the strength and durability of concrete structures.

2025-07-29

Understanding Prestressed Reinforced Ribbed Wire: A Key Component in Modern Construction

Prestressed reinforced ribbed wire is an innovative material widely used in the construction and decoration sectors, particularly within steel materials and wire ropes. This specialized wire combines the benefits of prestressing techniques with ribbed surface characteristics to provide superior strength, flexibility, and durability. Understanding the properties and applications of prestressed rein

2025-07-26

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction Table of Contents 1. Introduction to Prestressed Reinforced Ribbed Wire 2. What is Prestressed Reinforced Ribbed Wire? 3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire 3.1 Enhanced Strength and Load-Bearing Capacity 3.2 Durability and Longevity 3.3 Cost-Effective

2025-07-23