Understanding Uncoated Prestressed Wire: A Key Component in Construction

Release time:

2025-08-07

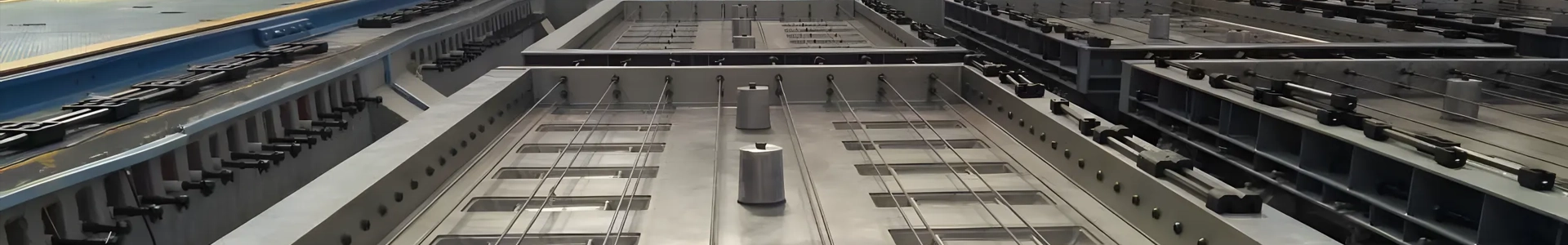

Uncoated prestressed wire is a crucial element in the construction and decorative materials sector, particularly in steel applications. This type of wire is designed to provide enhanced structural performance by being tensioned prior to the application of loads, thus improving the overall strength and durability of concrete structures. The primary advantage of uncoated prestressed wire lies in it

The primary advantage of uncoated prestressed wire lies in its ability to withstand tensile stresses. When concrete is cast, it is inherently strong in compression but weak in tension. By incorporating prestressed wire, engineers can overcome this limitation. The wire is placed in a concrete element and subjected to tensile forces before the concrete is poured. Once the concrete hardens, the tension is released, compressing the concrete and allowing it to support greater loads without cracking or deformation.

Uncoated prestressed wire typically comes in various diameters and strengths, making it versatile for numerous applications. It is commonly used in precast concrete elements such as beams, slabs, and walls, which are essential in modern construction. Additionally, its lightweight nature makes transportation and handling easier on job sites, which can contribute to overall project efficiency.

One of the critical considerations when using uncoated prestressed wire is its susceptibility to corrosion. As the name suggests, uncoated wire lacks any protective layer, making it more vulnerable to environmental factors, such as moisture and chemicals. Therefore, it is crucial for engineers and contractors to factor in the environmental conditions of the project site. In certain applications, protective measures, such as corrosion inhibitors or the use of coated wires, may be recommended.

Moreover, understanding the performance characteristics of uncoated prestressed wire is vital for ensuring the safety and longevity of structures. The wire is subject to strict quality control standards and testing prior to use, ensuring that it meets the necessary specifications for strength and durability. It is essential for construction professionals to consult relevant codes and standards when incorporating this material into their designs.

In conclusion, uncoated prestressed wire plays a fundamental role in the construction industry by enhancing the structural integrity of concrete elements. Its ability to manage tensile stresses effectively allows for the creation of stronger, more durable structures. However, careful consideration of its properties and potential vulnerabilities to corrosion is crucial for successful application. Employing this material wisely can lead to improved performance and longevity of construction projects, making it a valuable asset in the field of building and construction.

Latest News

Understanding Uncoated Prestressed Wire: A Key Component in Construction

Uncoated prestressed wire is a crucial element in the construction and decorative materials sector, particularly in steel applications. This type of wire is designed to provide enhanced structural performance by being tensioned prior to the application of loads, thus improving the overall strength and durability of concrete structures. The primary advantage of uncoated prestressed wire lies in it

2025-08-07

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction In the dynamic world of construction, material choices can significantly influence project outcomes. Among the myriad of options available, uncoated prestressed wire has emerged as a pivotal component in modern engineering. In this comprehensive article, we will delve into the multifaceted benefits of uncoated prestressed w

2025-08-04

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture Introduction to Prestressed Reinforced Ribbed Wire Prestressed reinforced ribbed wire is a crucial material in the field of modern architecture and construction. It combines the advantages of prestressing technology with the physical properties of ribbed wire, enhancing the strength and durability of concrete structures.

2025-07-29

Understanding Prestressed Reinforced Ribbed Wire: A Key Component in Modern Construction

Prestressed reinforced ribbed wire is an innovative material widely used in the construction and decoration sectors, particularly within steel materials and wire ropes. This specialized wire combines the benefits of prestressing techniques with ribbed surface characteristics to provide superior strength, flexibility, and durability. Understanding the properties and applications of prestressed rein

2025-07-26

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction Table of Contents 1. Introduction to Prestressed Reinforced Ribbed Wire 2. What is Prestressed Reinforced Ribbed Wire? 3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire 3.1 Enhanced Strength and Load-Bearing Capacity 3.2 Durability and Longevity 3.3 Cost-Effective

2025-07-23

Understanding High-Tensile Indented PC Wire: A Key Material in Construction

High-tensile indented PC wire, short for prestressed concrete wire, is an innovative steel material that has gained significant attention in the construction industry due to its excellent strength-to-weight ratio and durability. This wire is manufactured with indents on its surface, which enhances its bond with concrete, making it an ideal choice for various structural applications. One of the sta

2025-07-20