The Promising Future of Spiral Ribbed Steel Wire

Release time:

2025-03-05

In the ever-evolving landscape of construction materials, spiral ribbed steel wire is emerging as a leading player, poised to reshape the industry with its innovative design and unparalleled benefits.

In the ever-evolving landscape of construction materials, spiral ribbed steel wire is emerging as a leading player, poised to reshape the industry with its innovative design and unparalleled benefits. Recent developments in the construction sector indicate that this product may soon become a staple in civil engineering and infrastructure projects worldwide.

Spiral ribbed steel wire, characterized by its unique helical ribbing, offers significant advantages over traditional steel reinforcement bars. The spiral design enhances the bond between the steel and the concrete, leading to improved structural integrity and resilience. This feature is particularly vital in seismic zones, where buildings must withstand the forces of nature. Experts believe that the adoption of spiral ribbed steel wire could substantially reduce the risk of structural failure during earthquakes, safeguarding lives and properties.

Industry analysts have noted a rising demand for high-performance construction materials, driven by stringent building codes and the need for sustainable practices. Spiral ribbed steel wire fits this narrative perfectly, as it not only meets rigorous safety standards but also promises longevity and durability. Unlike conventional reinforcement options, it exhibits superior resistance to corrosion, thereby extending the lifespan of concrete structures and minimizing maintenance costs over time.

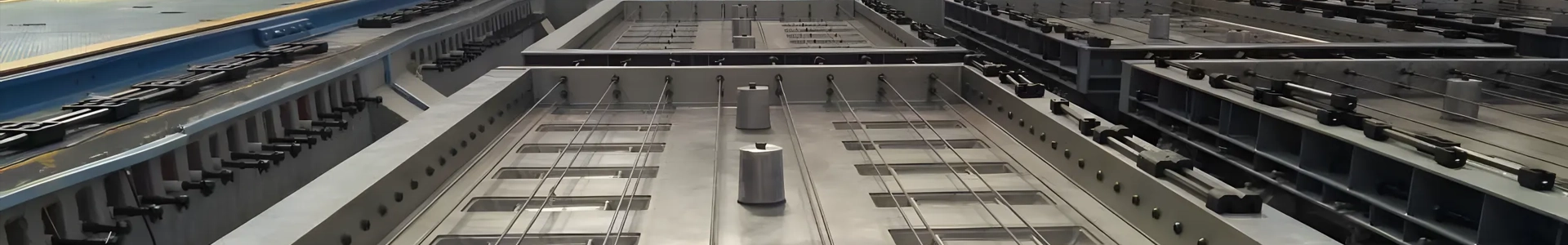

Moreover, the production process for spiral ribbed steel wire is becoming increasingly efficient, thanks to advancements in manufacturing technologies. Companies are investing in state-of-the-art facilities that utilize automated processes to produce high-quality steel products at competitive prices. This shift is expected to lower production costs and make spiral ribbed steel wire an economically viable option for a broader range of projects.

The global construction market is also experiencing a shift towards sustainable practices, prompting a reevaluation of material choices. The use of spiral ribbed steel wire aligns with these sustainability goals. By improving the lifespan and performance of concrete structures, this innovative material reduces the frequency of repairs and replacements, ultimately contributing to less waste and a smaller carbon footprint.

Recent projects around the world have showcased the potential of spiral ribbed steel wire. Notably, several high-profile infrastructure developments have incorporated this material, resulting in successful outcomes and heightened interest from engineers and contractors. As the industry witnesses these tangible benefits, more stakeholders are likely to consider spiral ribbed steel wire for their upcoming projects.

The future appears bright for spiral ribbed steel wire, with experts predicting increased adoption across sectors, including residential, commercial, and industrial construction. The ongoing research and development efforts aimed at enhancing its properties further bolster its market position. Additionally, the growing trend towards modular and prefabricated construction is expected to open new avenues for the utilization of this versatile material.

As construction professionals continue to prioritize safety, efficiency, and sustainability, the spotlight is firmly on spiral ribbed steel wire. With its excellent performance characteristics and cost-effectiveness, it is set to become a game-changer in the industry. As stakeholders embrace innovation, the potential for spiral ribbed steel wire to revolutionize construction practices cannot be overstated.

In conclusion, the outlook for spiral ribbed steel wire is promising, underscoring a significant shift in how the construction industry approaches reinforcement materials. With its proven advantages and alignment with modern construction demands, it stands ready to redefine structural integrity and pave the way for safer, more sustainable building practices in the years to come.

Latest News

Why Choose Uncoated Prestressed Wire for Your Next Building Project?

Why Choose Uncoated Prestressed Wire for Your Next Building Project? Understanding Uncoated Prestressed Wire In the world of construction and architectural design, the materials you choose can significantly impact the overall success and longevity of a project. One material that stands out in the realm of concrete reinforcement is uncoated prestressed wire. This article delves into the advantages

2025-08-10

Understanding Uncoated Prestressed Wire: A Key Component in Construction

Uncoated prestressed wire is a crucial element in the construction and decorative materials sector, particularly in steel applications. This type of wire is designed to provide enhanced structural performance by being tensioned prior to the application of loads, thus improving the overall strength and durability of concrete structures. The primary advantage of uncoated prestressed wire lies in it

2025-08-07

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction In the dynamic world of construction, material choices can significantly influence project outcomes. Among the myriad of options available, uncoated prestressed wire has emerged as a pivotal component in modern engineering. In this comprehensive article, we will delve into the multifaceted benefits of uncoated prestressed w

2025-08-04

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture Introduction to Prestressed Reinforced Ribbed Wire Prestressed reinforced ribbed wire is a crucial material in the field of modern architecture and construction. It combines the advantages of prestressing technology with the physical properties of ribbed wire, enhancing the strength and durability of concrete structures.

2025-07-29

Understanding Prestressed Reinforced Ribbed Wire: A Key Component in Modern Construction

Prestressed reinforced ribbed wire is an innovative material widely used in the construction and decoration sectors, particularly within steel materials and wire ropes. This specialized wire combines the benefits of prestressing techniques with ribbed surface characteristics to provide superior strength, flexibility, and durability. Understanding the properties and applications of prestressed rein

2025-07-26

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction Table of Contents 1. Introduction to Prestressed Reinforced Ribbed Wire 2. What is Prestressed Reinforced Ribbed Wire? 3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire 3.1 Enhanced Strength and Load-Bearing Capacity 3.2 Durability and Longevity 3.3 Cost-Effective

2025-07-23