The Evolution of Etched Steel Wire: A Breakthrough in Manufacturing Technology

Release time:

2025-03-05

In recent years, the manufacturing sector has witnessed remarkable advancements, and one of the most significant developments is the evolution of etched steel wire.

In recent years, the manufacturing sector has witnessed remarkable advancements, and one of the most significant developments is the evolution of etched steel wire. This innovative product has rapidly gained traction in various industries, from construction to automotive, due to its unique properties and versatile applications.

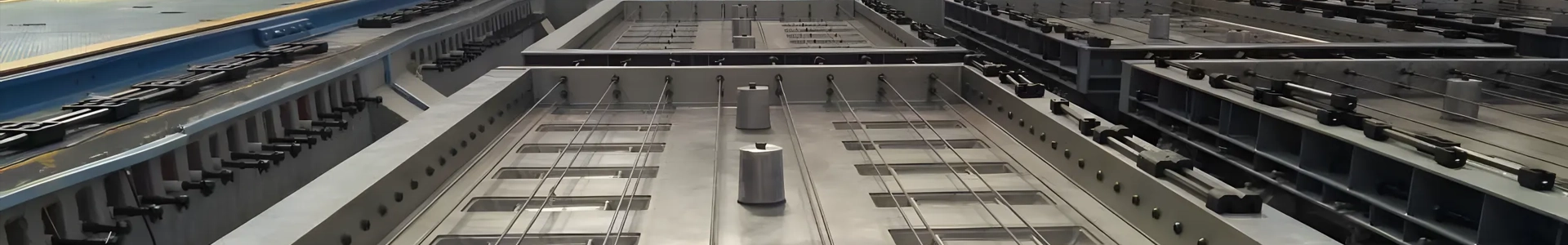

Etched steel wire, characterized by its precise surface textures and enhanced mechanical properties, has transformed traditional wire manufacturing processes. The technique involves using chemical etching to create intricate patterns on the steel surface, resulting in improved adhesion for coatings and a reduction in friction during application. This process not only boosts the performance of the wire but also extends its lifespan, making it an attractive option for manufacturers seeking efficiency and sustainability.

Recent reports highlight the growing demand for etched steel wire in the automotive industry, where lightweight materials are increasingly essential for fuel efficiency and performance. The ability to customize wire properties through etching allows engineers to design components that meet specific requirements without compromising strength or durability. As automakers strive to meet stricter environmental regulations, the adoption of etched steel wire has become a strategic advantage.

Moreover, the construction industry has also embraced this innovation. Etched steel wire is being utilized in reinforced concrete applications, providing superior bonding with concrete and enhancing the overall structural integrity of buildings and infrastructure. As urbanization accelerates across the globe, the need for robust and reliable construction materials has never been more critical. Manufacturers are racing to keep pace with the rising demand, and etched steel wire is leading the charge.

The technology behind etched steel wire continues to evolve, with researchers exploring new techniques to enhance its properties further. Companies are investing in R&D to develop advanced etching methods, which could offer even greater customization and performance benefits. This commitment to innovation is reflected in recent partnerships between universities and manufacturers, aimed at pushing the boundaries of what is possible with etched materials.

Industry experts believe that the etched steel wire market is poised for significant growth in the coming years. A recent market analysis revealed that the global etched steel wire market is projected to expand at a compound annual growth rate (CAGR) of over 5% through 2030. This growth is expected to be driven by increasing applications in various sectors and the ongoing shift towards more sustainable manufacturing practices.

As the demand for etched steel wire continues to rise, manufacturers are also focusing on sustainability. The etching process can be designed to minimize waste and energy consumption, aligning with the broader trend towards environmentally friendly production methods. Companies are increasingly recognizing that sustainable practices not only benefit the planet but also enhance their brand reputation and competitiveness in the marketplace.

In conclusion, the evolution of etched steel wire marks a significant milestone in the manufacturing landscape. Its unique properties and versatility have opened doors to new applications across various industries, driving innovation and sustainability. As this market continues to grow, it is clear that etched steel wire is not just a trend but a fundamental shift in how materials are produced and utilized in the modern manufacturing era. With ongoing research and development, the future of etched steel wire looks promising, offering endless possibilities for manufacturers and consumers alike.

Latest News

Why Choose Uncoated Prestressed Wire for Your Next Building Project?

Why Choose Uncoated Prestressed Wire for Your Next Building Project? Understanding Uncoated Prestressed Wire In the world of construction and architectural design, the materials you choose can significantly impact the overall success and longevity of a project. One material that stands out in the realm of concrete reinforcement is uncoated prestressed wire. This article delves into the advantages

2025-08-10

Understanding Uncoated Prestressed Wire: A Key Component in Construction

Uncoated prestressed wire is a crucial element in the construction and decorative materials sector, particularly in steel applications. This type of wire is designed to provide enhanced structural performance by being tensioned prior to the application of loads, thus improving the overall strength and durability of concrete structures. The primary advantage of uncoated prestressed wire lies in it

2025-08-07

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction In the dynamic world of construction, material choices can significantly influence project outcomes. Among the myriad of options available, uncoated prestressed wire has emerged as a pivotal component in modern engineering. In this comprehensive article, we will delve into the multifaceted benefits of uncoated prestressed w

2025-08-04

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture Introduction to Prestressed Reinforced Ribbed Wire Prestressed reinforced ribbed wire is a crucial material in the field of modern architecture and construction. It combines the advantages of prestressing technology with the physical properties of ribbed wire, enhancing the strength and durability of concrete structures.

2025-07-29

Understanding Prestressed Reinforced Ribbed Wire: A Key Component in Modern Construction

Prestressed reinforced ribbed wire is an innovative material widely used in the construction and decoration sectors, particularly within steel materials and wire ropes. This specialized wire combines the benefits of prestressing techniques with ribbed surface characteristics to provide superior strength, flexibility, and durability. Understanding the properties and applications of prestressed rein

2025-07-26

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction Table of Contents 1. Introduction to Prestressed Reinforced Ribbed Wire 2. What is Prestressed Reinforced Ribbed Wire? 3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire 3.1 Enhanced Strength and Load-Bearing Capacity 3.2 Durability and Longevity 3.3 Cost-Effective

2025-07-23