Understanding the Advantages of Grooved Prestressed PC Wire in Modern Construction

Release time:

2025-06-17

Understanding the Advantages of Grooved Prestressed PC Wire in Modern Construction Table of Contents What is Grooved Prestressed PC Wire? The Science Behind Prestressing in Construction Key Benefits of Grooved Prestressed Wire Enhanced Durability Improved Load-Bearing Capacity Reduced Cracking and Failure Cost-Effectiveness

Understanding the Advantages of Grooved Prestressed PC Wire in Modern Construction

Table of Contents

- What is Grooved Prestressed PC Wire?

- The Science Behind Prestressing in Construction

- Key Benefits of Grooved Prestressed Wire

- Applications of Grooved Prestressed Wire in Construction

- Installation Techniques for Grooved Prestressed Wire

- Maintenance and Care of Grooved Prestressed Wire

- Frequently Asked Questions

- Conclusion

What is Grooved Prestressed PC Wire?

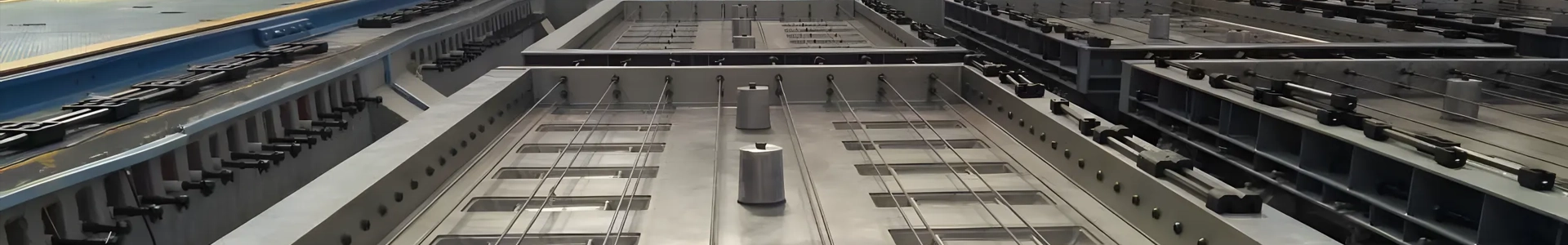

Grooved prestressed PC wire is a specialized type of wire used predominantly in the construction of concrete structures. Its unique grooved design allows for an increased surface area, which enhances its bonding with concrete. This bond is critical in the process of prestressing, where the wire is tensioned before the concrete is poured, creating a compressive force that strengthens the entire structure.

The use of grooved prestressed PC wire has gained significant attention due to its ability to improve the performance of concrete elements, making it a go-to choice for engineers and architects seeking innovative solutions for modern construction challenges.

The Science Behind Prestressing in Construction

Prestressing is a technique that involves applying a pre-compressive force to concrete elements, helping them withstand tensile stresses that occur under load. Traditional concrete is strong in compression but weak in tension, making it susceptible to cracking and failure when subjected to tensile forces.

Grooved prestressed PC wire plays a pivotal role in this process. By tensioning the wire before the concrete is cast, a compressive force is introduced that counteracts tensile stresses once the structure is in use. This results in a more robust and durable construction that can handle various loads without compromising safety or structural integrity.

Key Benefits of Grooved Prestressed Wire

Enhanced Durability

One of the most significant advantages of using grooved prestressed PC wire is its enhanced durability. The grooved texture increases the mechanical interlock between the wire and the surrounding concrete. This results in improved load transfer capabilities and minimizes the risk of slippage or separation over time.

Furthermore, the treatment of the wire often includes corrosion-resistant coatings, which help protect against environmental factors that could lead to degradation. This durability is essential for structures exposed to harsh conditions, such as bridges, parking garages, and high-rise buildings.

Improved Load-Bearing Capacity

Grooved prestressed PC wire increases the load-bearing capacity of concrete structures significantly. The pre-compressive forces introduced by the tensioned wire allow the concrete to handle greater loads without experiencing deformation or failure.

This makes it particularly advantageous in applications where heavy loads are expected, such as in high-rise buildings, bridges, and industrial facilities. With grooved prestressed wire, engineers can design slimmer and lighter structures while ensuring that they meet safety and performance standards.

Reduced Cracking and Failure

Cracking in concrete is a common issue that can lead to serious structural problems if not managed effectively. Grooved prestressed PC wire helps mitigate this risk by distributing tensile stresses more evenly throughout the concrete.

By counteracting the forces that lead to cracking, this type of wire significantly reduces the likelihood of structural failures, thereby enhancing the longevity and reliability of the construction. This benefit is particularly important in regions prone to seismic activity, where structural integrity is paramount.

Cost-Effectiveness

While the initial cost of grooved prestressed PC wire may be higher than traditional reinforcement methods, the long-term savings it offers make it a cost-effective choice. The durability and reduced likelihood of repairs mean that structures utilizing this wire will require less maintenance over their lifespan.

Additionally, the ability to create lighter and slimmer designs can lead to savings in materials and construction time, further enhancing overall project efficiency and profitability.

Applications of Grooved Prestressed Wire in Construction

Grooved prestressed PC wire is utilized across various construction applications due to its versatility and performance benefits. Some common applications include:

Bridges

In bridge construction, the need for materials that can handle dynamic loads and stress is critical. Grooved prestressed wire is often employed to enhance the load capacity and durability of bridge structures, ensuring they remain safe and functional over time.

Commercial Buildings

For commercial buildings, where aesthetics and structural integrity are equally important, grooved prestressed PC wire provides the necessary strength to support large spans and open floor plans while maintaining a lightweight build.

Parking Structures

Parking garages face unique challenges due to the weight of vehicles and the need for wide columns and beams. Grooved prestressed wire helps distribute loads effectively, reducing the risk of cracking and extending the lifespan of these structures.

Water Retaining Structures

In applications like water tanks and reservoirs, grooved prestressed wire enhances the structural integrity required to withstand internal pressure and environmental conditions. Its durability ensures that these vital structures remain functional for years.

Installation Techniques for Grooved Prestressed Wire

The installation of grooved prestressed PC wire requires careful planning and execution to ensure optimal performance. Below are some essential techniques involved in the installation process:

Preparation of Concrete Elements

Before the installation of grooved prestressed wire, concrete elements must be prepared properly. This includes ensuring that all surfaces are clean and free from contaminants that could interfere with the bond between the wire and concrete.

Tensioning the Wire

The tensioning process is critical. The wire must be stretched to the specified tension level before the concrete is poured. This process often involves specialized equipment that can accurately measure and apply the necessary tension.

Bonding with Concrete

Once the wire is tensioned, the concrete is poured around it. The grooves in the wire allow for better bonding, which is essential for distributing forces effectively once the structure is in use. Proper curing of the concrete also ensures optimal performance.

Maintenance and Care of Grooved Prestressed Wire

Maintaining structures that incorporate grooved prestressed wire involves regular inspections and upkeep. Key maintenance practices include:

Regular Inspections

Routine inspections should be conducted to check for any signs of wear, corrosion, or cracking in the surrounding concrete. Early detection of issues can prevent more significant problems down the line.

Corrosion Protection

In environments where corrosion is a concern, applying protective coatings or sealants can help preserve the integrity of the wire and extend the lifespan of the structure.

Load Monitoring

Monitoring the loads applied to structures utilizing grooved prestressed wire can provide valuable data on performance and help in making informed decisions regarding maintenance and repairs.

Frequently Asked Questions

1. What is the lifespan of grooved prestressed PC wire?

The lifespan of grooved prestressed PC wire can vary, but with proper installation and maintenance, it can last several decades.

2. How does grooved prestressed wire compare to traditional reinforcement methods?

Grooved prestressed wire offers better load-bearing capacity, reduced cracking, and increased durability compared to traditional reinforcement methods.

3. Can grooved prestressed wire be used in seismic areas?

Yes, its ability to enhance structural integrity makes it an excellent choice for construction in seismic areas.

4. What are the environmental impacts of using grooved prestressed wire?

Using durable materials like grooved prestressed wire can lead to less frequent repairs and replacements, making it a more sustainable choice over the long term.

5. Is specialized training required for installation?

Yes, specialized training is often necessary to ensure that the wire is tensioned correctly and installed in accordance with engineering standards.

Conclusion

In conclusion, grooved prestressed PC wire represents a significant advancement in construction technology, offering enhanced durability, improved load-bearing capacity, and reduced cracking. Its applications across various sectors illustrate its versatility and the growing demand for innovative solutions in the construction industry. By understanding the benefits and proper installation techniques of grooved prestressed wire, construction professionals can make informed decisions that lead to safer, more efficient, and cost-effective building practices. This innovative material is not just a trend; it is a cornerstone of modern construction that can revolutionize how we build for the future.

Latest News

Why Choose Uncoated Prestressed Wire for Your Next Building Project?

Why Choose Uncoated Prestressed Wire for Your Next Building Project? Understanding Uncoated Prestressed Wire In the world of construction and architectural design, the materials you choose can significantly impact the overall success and longevity of a project. One material that stands out in the realm of concrete reinforcement is uncoated prestressed wire. This article delves into the advantages

2025-08-10

Understanding Uncoated Prestressed Wire: A Key Component in Construction

Uncoated prestressed wire is a crucial element in the construction and decorative materials sector, particularly in steel applications. This type of wire is designed to provide enhanced structural performance by being tensioned prior to the application of loads, thus improving the overall strength and durability of concrete structures. The primary advantage of uncoated prestressed wire lies in it

2025-08-07

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction In the dynamic world of construction, material choices can significantly influence project outcomes. Among the myriad of options available, uncoated prestressed wire has emerged as a pivotal component in modern engineering. In this comprehensive article, we will delve into the multifaceted benefits of uncoated prestressed w

2025-08-04

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture Introduction to Prestressed Reinforced Ribbed Wire Prestressed reinforced ribbed wire is a crucial material in the field of modern architecture and construction. It combines the advantages of prestressing technology with the physical properties of ribbed wire, enhancing the strength and durability of concrete structures.

2025-07-29

Understanding Prestressed Reinforced Ribbed Wire: A Key Component in Modern Construction

Prestressed reinforced ribbed wire is an innovative material widely used in the construction and decoration sectors, particularly within steel materials and wire ropes. This specialized wire combines the benefits of prestressing techniques with ribbed surface characteristics to provide superior strength, flexibility, and durability. Understanding the properties and applications of prestressed rein

2025-07-26

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction Table of Contents 1. Introduction to Prestressed Reinforced Ribbed Wire 2. What is Prestressed Reinforced Ribbed Wire? 3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire 3.1 Enhanced Strength and Load-Bearing Capacity 3.2 Durability and Longevity 3.3 Cost-Effective

2025-07-23