The Importance of Serrated Prestressed Steel Wire in Load-Bearing Structures

Release time:

2025-06-11

The Importance of Serrated Prestressed Steel Wire in Load-Bearing Structures Table of Contents 1. Introduction to Serrated Prestressed Steel Wire 2. Understanding Load-Bearing Structures 3. What is Serrated Prestressed Steel Wire? 4. Advantages of Serrated Prestressed Steel Wire 5. Applications in Load-Bearing Structures 6. Design Considerations for Using Serrated Wire 7. Installati

The Importance of Serrated Prestressed Steel Wire in Load-Bearing Structures

Table of Contents

- 1. Introduction to Serrated Prestressed Steel Wire

- 2. Understanding Load-Bearing Structures

- 3. What is Serrated Prestressed Steel Wire?

- 4. Advantages of Serrated Prestressed Steel Wire

- 5. Applications in Load-Bearing Structures

- 6. Design Considerations for Using Serrated Wire

- 7. Installation Techniques for Serrated Prestressed Steel Wire

- 8. The Future of Serrated Prestressed Steel Wire in Construction

- 9. FAQs

- 10. Conclusion

1. Introduction to Serrated Prestressed Steel Wire

Serrated prestressed steel wire plays an essential role in modern construction, especially in load-bearing structures. Its unique properties enable engineers to create resilient, durable frameworks that can withstand significant tension and compression forces. In this article, we will explore the significance of serrated prestressed steel wire, its advantages, applications, and future prospects in the construction industry.

2. Understanding Load-Bearing Structures

Load-bearing structures are designed to support weight and resist external forces, ensuring safety and stability. These structures are essential in various applications, from residential buildings to bridges and commercial complexes. The choice of materials used in these structures directly impacts their performance and longevity. As demands for durability and efficiency increase, the need for advanced materials like serrated prestressed steel wire has become apparent.

3. What is Serrated Prestressed Steel Wire?

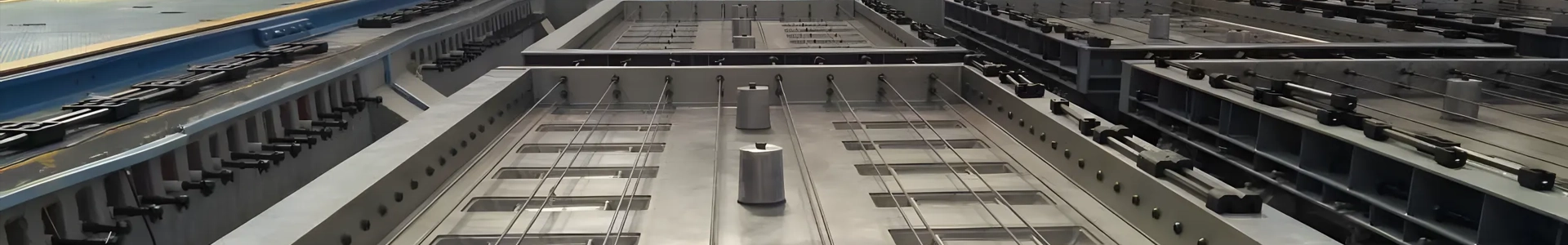

Serrated prestressed steel wire is a type of high-strength wire characterized by its serrated surface profile. This design feature enhances the wire's grip within concrete and other composites, improving bond strength and load distribution. The wire undergoes a prestressing process, which involves applying tension to the wire before it is embedded in concrete. This tension counteracts the tensile forces experienced by the structure, significantly increasing its load-bearing capacity.

The Manufacturing Process of Serrated Wire

The manufacturing process of serrated prestressed steel wire involves drawing high-carbon steel into thin strands and shaping the surface to create serrations. The serrated edges improve the mechanical interlock between the wire and surrounding materials, enhancing performance. After shaping, the wire is typically subjected to heat treatment, increasing its tensile strength and elasticity.

4. Advantages of Serrated Prestressed Steel Wire

Serrated prestressed steel wire offers numerous advantages that make it an attractive choice for civil engineering applications.

Enhanced Load-Bearing Capacity

The primary benefit of serrated prestressed steel wire is its enhanced load-bearing capacity. The combination of pre-tensioning and the serrated surface allows the wire to effectively distribute loads across the structure, reducing stress on individual components.

Improved Durability

Due to its high strength and corrosion resistance, serrated prestressed steel wire significantly enhances the durability of load-bearing structures. Unlike traditional materials, it can withstand harsh environmental conditions, reducing maintenance costs and extending the lifespan of structures.

Reduction in Structural Weight

Serrated prestressed steel wire allows for the design of lighter structures without compromising strength. By utilizing high-strength materials, engineers can create efficient designs that require less material but provide the same or greater load-bearing capacity.

Versatility in Design

The flexibility of serrated prestressed steel wire makes it suitable for various architectural designs. Whether it’s for residential buildings, bridges, or parking garages, this material can adapt to different structural needs, allowing for innovative and creative designs.

5. Applications in Load-Bearing Structures

Serrated prestressed steel wire is utilized in various applications across the construction industry, enhancing structural performance in the following ways:

Bridges

In bridge construction, serrated prestressed steel wire is commonly used to enhance the tensile strength of components, ensuring safety under heavy loads and dynamic forces. Its ability to endure environmental factors like corrosion makes it a preferred choice for long-span bridges.

High-Rise Buildings

High-rise buildings benefit significantly from serrated prestressed steel wire, as it allows for slimmer columns and beams without sacrificing strength. This not only reduces the overall weight of the structure but also maximizes usable space within the building.

Parking Structures

In parking structures, the need for efficient use of space is critical. Serrated prestressed steel wire provides the necessary strength to create multi-level designs while keeping material costs low.

Industrial Applications

Serrated prestressed steel wire finds applications in industrial settings, including heavy machinery foundations and storage facilities. Its strength and durability ensure that structures can withstand heavy loads and operational stresses.

6. Design Considerations for Using Serrated Wire

When incorporating serrated prestressed steel wire into load-bearing structures, several design considerations must be addressed:

Load Requirements

Understanding the load requirements of the structure is critical. Engineers must calculate the anticipated loads, including live loads, dead loads, and environmental factors, to determine the appropriate specifications for serrated wire.

Bonding with Concrete

The bonding characteristics between serrated prestressed steel wire and concrete are vital for performance. Proper consideration of the bond strength and the concrete mix design can enhance the overall effectiveness of the prestressing system.

Environmental Factors

Environmental factors, including temperature, humidity, and exposure to chemicals, can affect the performance of serrated prestressed steel wire. Engineers must account for these elements during the design phase to ensure longevity and durability.

7. Installation Techniques for Serrated Prestressed Steel Wire

The installation of serrated prestressed steel wire requires careful planning and execution to ensure its effectiveness in load-bearing structures.

Preparation of the Site

Before installation, the site must be adequately prepared, including the placement of forms and reinforcement. This preparation is crucial to ensure that the serrated wire is properly positioned within the concrete.

Tensioning Process

The tensioning of the wire must be performed with precision. Engineers typically use hydraulic jacks to apply the required tension to the wire before the concrete is poured. This process must be monitored closely to achieve the desired prestressing force.

Curing of Concrete

After installation, the concrete must be cured correctly to ensure optimal bond strength with the serrated wire. Adequate curing time and environmental control are essential for achieving the desired structural performance.

8. The Future of Serrated Prestressed Steel Wire in Construction

As the construction industry evolves, the demand for high-performance materials like serrated prestressed steel wire will continue to grow. Innovations in material science and engineering practices will likely lead to enhanced properties and applications of this essential component.

Integration with Smart Technologies

The future may see serrated prestressed steel wire integrated with smart technologies, allowing for real-time monitoring of structural health and performance. Sensors embedded within the wire could provide valuable data, enhancing safety and maintenance practices.

Sustainability Considerations

As sustainability becomes a priority within the construction sector, the development of eco-friendly serrated prestressed steel wire could emerge. Innovations that reduce the carbon footprint during manufacturing and promote recyclability will likely be at the forefront of future advancements.

9. FAQs

What is the primary use of serrated prestressed steel wire?

Serrated prestressed steel wire is primarily used in load-bearing structures such as bridges, high-rise buildings, and industrial applications to improve their strength and durability.

How does serration improve the performance of steel wire?

Serration enhances the mechanical interlock between the wire and surrounding materials, improving bond strength and load distribution, which is critical in load-bearing applications.

Can serrated prestressed steel wire be recycled?

Yes, serrated prestressed steel wire can be recycled, making it an environmentally friendly option for construction.

What factors influence the choice of serrated prestressed steel wire?

Factors influencing the choice include load requirements, environmental conditions, and specific structural design considerations.

How is tension applied to serrated prestressed steel wire during installation?

Tension is applied using hydraulic jacks, which allow for precise control over the amount of stress placed on the wire before the concrete is poured.

10. Conclusion

In summary, serrated prestressed steel wire is a vital component in the construction of load-bearing structures. Its unique properties offer substantial advantages in terms of strength, durability, and design versatility. As the construction industry continues to evolve, the importance of such materials will only increase, paving the way for innovative and sustainable building practices. Understanding the benefits and applications of serrated prestressed steel wire will empower engineers and architects to create safer, more efficient structures that meet the demands of modern society.

Latest News

Why Choose Uncoated Prestressed Wire for Your Next Building Project?

Why Choose Uncoated Prestressed Wire for Your Next Building Project? Understanding Uncoated Prestressed Wire In the world of construction and architectural design, the materials you choose can significantly impact the overall success and longevity of a project. One material that stands out in the realm of concrete reinforcement is uncoated prestressed wire. This article delves into the advantages

2025-08-10

Understanding Uncoated Prestressed Wire: A Key Component in Construction

Uncoated prestressed wire is a crucial element in the construction and decorative materials sector, particularly in steel applications. This type of wire is designed to provide enhanced structural performance by being tensioned prior to the application of loads, thus improving the overall strength and durability of concrete structures. The primary advantage of uncoated prestressed wire lies in it

2025-08-07

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction In the dynamic world of construction, material choices can significantly influence project outcomes. Among the myriad of options available, uncoated prestressed wire has emerged as a pivotal component in modern engineering. In this comprehensive article, we will delve into the multifaceted benefits of uncoated prestressed w

2025-08-04

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture Introduction to Prestressed Reinforced Ribbed Wire Prestressed reinforced ribbed wire is a crucial material in the field of modern architecture and construction. It combines the advantages of prestressing technology with the physical properties of ribbed wire, enhancing the strength and durability of concrete structures.

2025-07-29

Understanding Prestressed Reinforced Ribbed Wire: A Key Component in Modern Construction

Prestressed reinforced ribbed wire is an innovative material widely used in the construction and decoration sectors, particularly within steel materials and wire ropes. This specialized wire combines the benefits of prestressing techniques with ribbed surface characteristics to provide superior strength, flexibility, and durability. Understanding the properties and applications of prestressed rein

2025-07-26

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction Table of Contents 1. Introduction to Prestressed Reinforced Ribbed Wire 2. What is Prestressed Reinforced Ribbed Wire? 3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire 3.1 Enhanced Strength and Load-Bearing Capacity 3.2 Durability and Longevity 3.3 Cost-Effective

2025-07-23