How Serrated Prestressed Steel Wire Enhances Project Flexibility

Release time:

2025-06-05

How Serrated Prestressed Steel Wire Enhances Project Flexibility Introduction to Serrated Prestressed Steel Wire Serrated prestressed steel wire stands at the forefront of modern construction materials, offering unparalleled benefits that enhance project flexibility. This innovative material is engineered to deliver superior strength and adaptability, making it an ideal choice for a wide range of

How Serrated Prestressed Steel Wire Enhances Project Flexibility

Introduction to Serrated Prestressed Steel Wire

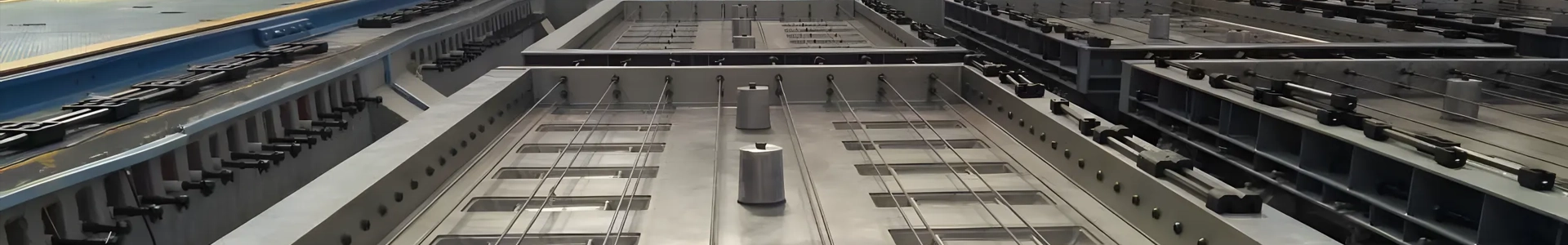

Serrated prestressed steel wire stands at the forefront of modern construction materials, offering unparalleled benefits that enhance project flexibility. This innovative material is engineered to deliver superior strength and adaptability, making it an ideal choice for a wide range of applications in construction and design.

The Unique Properties of Serrated Prestressed Steel Wire

Serrated prestressed steel wire is distinctively designed with serrations along its length. These features provide multiple advantages:

1. Increased Grip and Bonding

The serrated texture significantly enhances the grip between the wire and concrete. This improved bonding capability allows for better load distribution and minimizes the likelihood of slippage, which is crucial in ensuring structural integrity.

2. Enhanced Tensile Strength

Serrated prestressed steel wire boasts a remarkable tensile strength that far exceeds traditional options. This property allows structures to bear heavier loads, making it particularly useful in high-stress applications such as bridges and high-rise buildings.

3. Superior Fatigue Resistance

Regular steel wires are susceptible to fatigue over time, leading to failure under prolonged stress. However, the unique composition and design of serrated prestressed steel wires provide enhanced resistance to fatigue, ensuring longevity and reliability in various environments.

Applications of Serrated Prestressed Steel Wire in Construction

Serrated prestressed steel wire is utilized in various construction applications, highlighting its versatility and effectiveness.

1. Precast Concrete Elements

In the production of precast concrete elements, serrated prestressed steel wire plays a critical role. It ensures that these elements can withstand the demands of heavy loads and environmental stressors while maintaining their structural integrity.

2. Suspension Bridges

The tensile strength and bonding characteristics of serrated prestressed steel wire make it an excellent choice for suspension bridges. Its ability to maintain flexibility while securely holding loads allows for innovative designs and longer spans in bridge construction.

3. High-Rise Buildings

In high-rise buildings, where wind and seismic forces are significant concerns, serrated prestressed steel wire provides the necessary reinforcement. Its flexibility accommodates building movements, reducing the risk of structural damage during extreme weather conditions.

How Serrated Prestressed Steel Wire Enhances Project Flexibility

The flexibility offered by serrated prestressed steel wire is a game changer in the construction industry.

1. Design Adaptability

One of the most significant advantages of serrated prestressed steel wire is its adaptability in design. Engineers can utilize this material in various configurations, tailoring it to meet specific project requirements without compromising on safety or performance.

2. Reduced Construction Time

The ability to efficiently integrate serrated prestressed steel wire into construction processes can lead to reduced timelines. With fewer materials needed to achieve the same structural strength, projects can be completed more swiftly.

3. Cost Efficiency

While the initial investment in serrated prestressed steel wire might be higher than standard materials, its long-term benefits can lead to significant cost savings. Reduced maintenance, longer lifespan, and lower likelihood of repair all contribute to its cost efficiency.

Comparative Analysis: Serrated vs. Traditional Steel Wire

To understand the advantages of serrated prestressed steel wire, it’s essential to compare it with traditional steel wire.

1. Mechanical Properties

Serrated prestressed steel wire exhibits superior mechanical properties, including higher tensile strength and fatigue resistance, compared to traditional steel wire. This leads to enhanced performance in critical applications.

2. Installation Process

The installation of serrated prestressed steel wire is often more efficient than traditional methods. The improved grip and bonding reduce the complexity of the installation process, making it easier for construction teams to implement.

Future Trends in the Use of Serrated Prestressed Steel Wire

As construction technology evolves, the use of serrated prestressed steel wire is expected to increase.

1. Innovations in Material Science

Advancements in material science will likely yield even stronger and more versatile forms of serrated prestressed steel wire, broadening its applications even further.

2. Sustainable Construction Practices

With the increasing emphasis on sustainability, serrated prestressed steel wire can contribute to greener practices by reducing material waste and extending the lifecycle of constructions.

Frequently Asked Questions (FAQs)

1. What is serrated prestressed steel wire?

Serrated prestressed steel wire is a specialized construction material designed with serrations that enhance grip and bonding, providing superior strength and flexibility in various engineering applications.

2. How does serrated prestressed steel wire improve structural integrity?

By providing better bonding with concrete and distributing loads evenly, serrated prestressed steel wire minimizes the likelihood of slippage and enhances the overall stability of structures.

3. Can serrated prestressed steel wire be used in earthquake-prone areas?

Yes, its flexibility and superior tensile strength make it an ideal choice for use in earthquake-prone regions, as it can accommodate building movements without compromising safety.

4. Is serrated prestressed steel wire more expensive than traditional steel wire?

While it may involve a higher initial cost, the long-term benefits such as reduced maintenance and increased lifespan often result in overall cost savings.

5. What projects benefit the most from using serrated prestressed steel wire?

High-stress projects like suspension bridges, high-rise buildings, and precast concrete applications benefit significantly from the use of serrated prestressed steel wire due to its unique properties.

Conclusion

Serrated prestressed steel wire represents a significant advancement in construction materials, offering exceptional strength, flexibility, and adaptability. Its unique properties not only enhance project flexibility but also contribute to improved safety and longevity in various applications. By integrating serrated prestressed steel wire into construction practices, engineers and architects can create more resilient structures that meet the demands of modern engineering challenges. As the industry continues to evolve, the adoption of such innovative materials will undoubtedly pave the way for more efficient and sustainable construction practices in the future.

Latest News

Why Choose Uncoated Prestressed Wire for Your Next Building Project?

Why Choose Uncoated Prestressed Wire for Your Next Building Project? Understanding Uncoated Prestressed Wire In the world of construction and architectural design, the materials you choose can significantly impact the overall success and longevity of a project. One material that stands out in the realm of concrete reinforcement is uncoated prestressed wire. This article delves into the advantages

2025-08-10

Understanding Uncoated Prestressed Wire: A Key Component in Construction

Uncoated prestressed wire is a crucial element in the construction and decorative materials sector, particularly in steel applications. This type of wire is designed to provide enhanced structural performance by being tensioned prior to the application of loads, thus improving the overall strength and durability of concrete structures. The primary advantage of uncoated prestressed wire lies in it

2025-08-07

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction In the dynamic world of construction, material choices can significantly influence project outcomes. Among the myriad of options available, uncoated prestressed wire has emerged as a pivotal component in modern engineering. In this comprehensive article, we will delve into the multifaceted benefits of uncoated prestressed w

2025-08-04

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture Introduction to Prestressed Reinforced Ribbed Wire Prestressed reinforced ribbed wire is a crucial material in the field of modern architecture and construction. It combines the advantages of prestressing technology with the physical properties of ribbed wire, enhancing the strength and durability of concrete structures.

2025-07-29

Understanding Prestressed Reinforced Ribbed Wire: A Key Component in Modern Construction

Prestressed reinforced ribbed wire is an innovative material widely used in the construction and decoration sectors, particularly within steel materials and wire ropes. This specialized wire combines the benefits of prestressing techniques with ribbed surface characteristics to provide superior strength, flexibility, and durability. Understanding the properties and applications of prestressed rein

2025-07-26

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction Table of Contents 1. Introduction to Prestressed Reinforced Ribbed Wire 2. What is Prestressed Reinforced Ribbed Wire? 3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire 3.1 Enhanced Strength and Load-Bearing Capacity 3.2 Durability and Longevity 3.3 Cost-Effective

2025-07-23