The Rising Applications of Spiral Ribbed Steel Wires in Modern Construction

Release time:

2025-03-05

In recent years, the construction industry has witnessed a transformative shift with the increasing use of spiral ribbed steel wires.

In recent years, the construction industry has witnessed a transformative shift with the increasing use of spiral ribbed steel wires. Known for their exceptional strength, flexibility, and durability, these innovative materials are becoming indispensable in various applications, ranging from infrastructure projects to architectural designs.

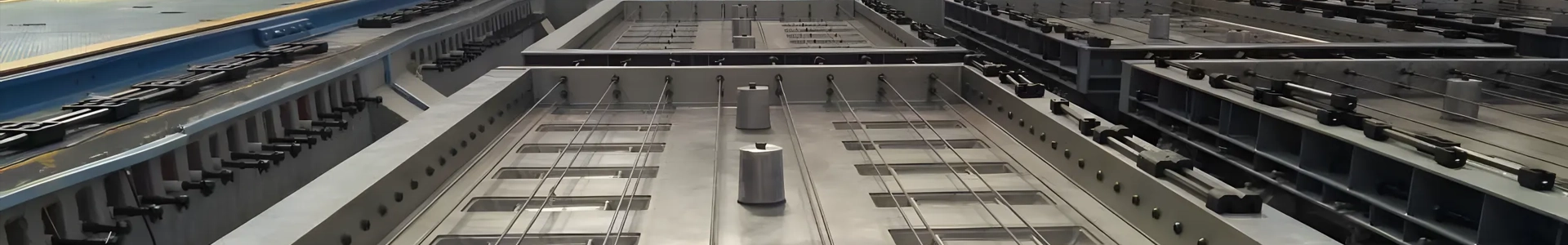

Spiral ribbed steel wires, characterized by their unique helical shape and ribbed surface, have garnered attention for their outstanding performance in enhancing the structural integrity of concrete structures. Unlike traditional smooth steel bars, the spiral design provides superior bonding with concrete, significantly improving load-bearing capacity and resistance to tensile forces. This innovation has led to a surge in interest from civil engineers and architects aiming to create safer and more resilient structures.

Recent reports indicate that major construction projects across the globe are increasingly incorporating spiral ribbed steel wires. For instance, a high-profile bridge project in Shanghai has adopted these wires in its design, promising enhanced stability and longevity. Engineers involved in the project have cited the material's ability to withstand extreme weather conditions and seismic activities as a key factor in their decision to utilize spiral ribbed steel wires.

Furthermore, the application of these wires is not limited to large-scale infrastructure. Residential and commercial buildings are also benefiting from their unique properties. Architects are now exploring creative design possibilities, utilizing spiral ribbed steel wires in innovative ways to achieve both aesthetic appeal and structural efficiency. This trend is particularly evident in eco-friendly buildings where sustainability is paramount. The reduced amount of steel required due to the enhanced performance of spiral ribbed wires contributes to lower carbon footprints in construction.

Experts predict that the demand for spiral ribbed steel wires will continue to rise as more construction firms recognize the long-term advantages of using this material. Industry analysts suggest that as urbanization accelerates and the need for durable infrastructure grows, the market for these specialized wires could expand significantly. Governments and private sectors alike are urged to invest in research and development to further enhance the properties of spiral ribbed steel, potentially leading to groundbreaking advancements in construction technology.

Moreover, the production techniques for these wires have evolved, making them more accessible and cost-effective. Manufacturers are adopting advanced methods that not only improve the quality of the wires but also streamline the production process. This shift is expected to reduce costs, making spiral ribbed steel wires a viable option for a broader range of projects, including those with tighter budgets.

As the construction landscape continues to evolve, the spiral ribbed steel wire is poised to play a pivotal role in shaping the future of building. With its impressive strength, adaptability, and sustainability, it represents a significant leap forward in materials technology. Stakeholders in the construction industry are encouraged to stay abreast of these developments, as the integration of spiral ribbed steel wires promises to enhance not only the safety and durability of structures but also the overall quality of modern architecture.

In conclusion, the rising applications of spiral ribbed steel wires are revolutionizing the construction industry. As more projects integrate this advanced material, it is clear that the future of construction lies in innovative solutions that prioritize strength, efficiency, and sustainability. With continued investment and research, spiral ribbed steel wires are set to redefine the standards of modern construction, paving the way for a safer and more resilient built environment.

Latest News

Why Choose Uncoated Prestressed Wire for Your Next Building Project?

Why Choose Uncoated Prestressed Wire for Your Next Building Project? Understanding Uncoated Prestressed Wire In the world of construction and architectural design, the materials you choose can significantly impact the overall success and longevity of a project. One material that stands out in the realm of concrete reinforcement is uncoated prestressed wire. This article delves into the advantages

2025-08-10

Understanding Uncoated Prestressed Wire: A Key Component in Construction

Uncoated prestressed wire is a crucial element in the construction and decorative materials sector, particularly in steel applications. This type of wire is designed to provide enhanced structural performance by being tensioned prior to the application of loads, thus improving the overall strength and durability of concrete structures. The primary advantage of uncoated prestressed wire lies in it

2025-08-07

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction

Exploring the Benefits of Uncoated Prestressed Wire in Modern Construction In the dynamic world of construction, material choices can significantly influence project outcomes. Among the myriad of options available, uncoated prestressed wire has emerged as a pivotal component in modern engineering. In this comprehensive article, we will delve into the multifaceted benefits of uncoated prestressed w

2025-08-04

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture

Top Applications of Prestressed Reinforced Ribbed Wire in Modern Architecture Introduction to Prestressed Reinforced Ribbed Wire Prestressed reinforced ribbed wire is a crucial material in the field of modern architecture and construction. It combines the advantages of prestressing technology with the physical properties of ribbed wire, enhancing the strength and durability of concrete structures.

2025-07-29

Understanding Prestressed Reinforced Ribbed Wire: A Key Component in Modern Construction

Prestressed reinforced ribbed wire is an innovative material widely used in the construction and decoration sectors, particularly within steel materials and wire ropes. This specialized wire combines the benefits of prestressing techniques with ribbed surface characteristics to provide superior strength, flexibility, and durability. Understanding the properties and applications of prestressed rein

2025-07-26

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction

Understanding the Incredible Benefits of Prestressed Reinforced Ribbed Wire in Construction Table of Contents 1. Introduction to Prestressed Reinforced Ribbed Wire 2. What is Prestressed Reinforced Ribbed Wire? 3. The Key Benefits of Using Prestressed Reinforced Ribbed Wire 3.1 Enhanced Strength and Load-Bearing Capacity 3.2 Durability and Longevity 3.3 Cost-Effective

2025-07-23