Why High-Tensile Ribbed PC Wire is Essential for Modern Construction

Release time:

2025-12-04

Why High-Tensile Ribbed PC Wire is Essential for Modern Construction Table of Contents Introduction Understanding High-Tensile Ribbed PC Wire Benefits of High-Tensile Ribbed PC Wire Durability and Strength Corrosion Resistance Cost-Effectiveness Applications in Modern Construction Commercial Structures

Why High-Tensile Ribbed PC Wire is Essential for Modern Construction

Table of Contents

- Introduction

- Understanding High-Tensile Ribbed PC Wire

- Benefits of High-Tensile Ribbed PC Wire

- Applications in Modern Construction

- High-Tensile Ribbed PC Wire vs Other Materials

- Installation Best Practices

- The Future of High-Tensile Ribbed PC Wire

- Frequently Asked Questions

- Conclusion

Introduction

In the realm of modern construction, the materials used can significantly impact the quality, safety, and longevity of structures. Among these materials, **high-tensile ribbed PC wire** stands out as an innovative solution that meets the growing demands of the industry. Its unique properties cater to a wide range of construction needs, making it an essential component in building strong, durable, and efficient structures. This article delves into the characteristics, benefits, applications, and future of high-tensile ribbed PC wire, demonstrating its importance in contemporary construction practices.

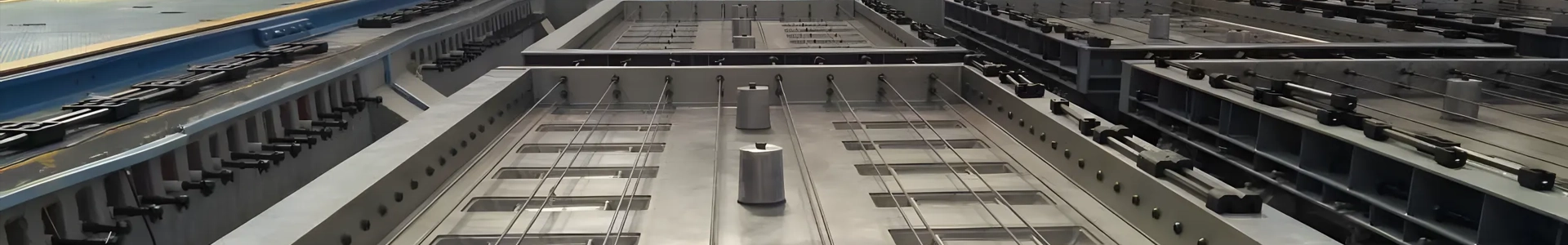

Understanding High-Tensile Ribbed PC Wire

High-tensile ribbed PC wire is a type of prestressed concrete wire, characterized by its ribbed texture and high tensile strength. This wire is typically made from high-quality steel, which is subjected to various manufacturing processes to enhance its mechanical properties. The ribbed surface improves bonding with concrete, which is crucial for prestressed applications, ensuring that forces are effectively transferred and distributed throughout the structure.

Manufacturing Process

The production of high-tensile ribbed PC wire involves several key steps:

1. **Wire Drawing**: High-strength steel rods are drawn through a series of dies to create the desired diameter and increase tensile strength.

2. **Ribbing**: The wire is subjected to a ribbing process, increasing its surface area and enhancing its grip on concrete.

3. **Heat Treatment**: The wire undergoes heat treatment to further improve its tensile properties and resistance to deformation.

This meticulous manufacturing process ensures that high-tensile ribbed PC wire is capable of withstanding extreme stress and environmental conditions, making it ideal for various construction applications.

Benefits of High-Tensile Ribbed PC Wire

The advantages of using high-tensile ribbed PC wire in construction are manifold. Understanding these benefits can help construction professionals make informed decisions about material selection.

Durability and Strength

One of the most significant benefits of high-tensile ribbed PC wire is its exceptional durability and strength. This wire can withstand immense loads without breaking or deforming, making it suitable for structures subjected to seismic activity or heavy traffic. The inherent tensile strength means that buildings can be designed with more slender profiles, saving material without compromising safety.

Corrosion Resistance

High-tensile ribbed PC wire is often treated to enhance its corrosion resistance. This is particularly important for construction in harsh environments, such as coastal areas or regions with high humidity. The corrosion-resistant properties extend the lifespan of a structure, reducing maintenance costs and increasing overall safety.

Cost-Effectiveness

Although the initial cost of high-tensile ribbed PC wire may be higher than traditional steel, its benefits often lead to lower overall project costs. The longevity and reduced maintenance needs of structures using this wire contribute to significant savings over time. Additionally, the efficiency of construction processes, due to lighter materials, can lead to decreased labor costs.

Applications in Modern Construction

High-tensile ribbed PC wire has found its way into numerous construction applications, where its strength and durability are paramount.

Commercial Structures

In commercial buildings, high-tensile ribbed PC wire is utilized for floors, beams, and columns, providing the necessary support for multi-story designs. Its ability to carry heavy loads makes it ideal for shopping centers, office buildings, and industrial complexes.

Residential Buildings

For residential construction, this wire is used in foundations, slabs, and reinforced walls. The enhanced strength allows for innovative architectural designs and efficient use of space, accommodating modern living requirements without compromising safety.

Infrastructure Projects

High-tensile ribbed PC wire plays a crucial role in infrastructure projects, including bridges, tunnels, and highways. Its durability ensures that these structures can withstand dynamic loads and environmental factors, contributing to public safety and longevity.

High-Tensile Ribbed PC Wire vs Other Materials

When comparing high-tensile ribbed PC wire to other construction materials, several key differences arise.

Steel Reinforcement

Traditional steel reinforcement bars (rebar) have been a staple in construction, but they lack the high tensile strength and improved bonding properties of ribbed PC wire. While rebar is effective, high-tensile ribbed PC wire can provide greater load-bearing capacity with less material, resulting in a more cost-effective solution.

Fiber-Reinforced Polymers

Fiber-reinforced polymers (FRPs) offer advantages in corrosion resistance but may lack the tensile strength required for heavy-duty applications. In contrast, high-tensile ribbed PC wire combines both tensile strength and durability, making it a more versatile choice for various construction scenarios.

Installation Best Practices

To maximize the benefits of high-tensile ribbed PC wire, following best practices during installation is essential.

Proper Handling

Care should be taken to handle high-tensile ribbed PC wire properly to avoid damage. This includes avoiding kinks or bends in the wire, which can compromise its strength.

Correct Placement

During installation, ensure that the wire is placed correctly within the concrete formwork. Adequate spacing and alignment are crucial for optimal performance and load distribution.

Quality Control

Implementing quality control measures during installation can help identify potential issues early. Regular inspections ensure that the wire is installed according to specifications and standards, contributing to the overall integrity of the structure.

The Future of High-Tensile Ribbed PC Wire

The future of high-tensile ribbed PC wire in construction looks promising, with ongoing research and development focused on improving its properties. Innovations in manufacturing processes may lead to even stronger and more corrosion-resistant variations. Additionally, the growing demand for sustainable construction practices might encourage the integration of high-tensile ribbed PC wire with eco-friendly materials.

Frequently Asked Questions

1. What is high-tensile ribbed PC wire?

High-tensile ribbed PC wire is a type of prestressed concrete wire known for its high tensile strength and ribbed surface that enhances bonding with concrete.

2. What are the primary advantages of using high-tensile ribbed PC wire?

The main advantages include durability, corrosion resistance, and cost-effectiveness, making it ideal for a variety of construction applications.

3. In what types of construction projects is high-tensile ribbed PC wire typically used?

This wire is commonly used in commercial buildings, residential structures, and infrastructure projects like bridges and tunnels.

4. How does high-tensile ribbed PC wire compare to traditional steel reinforcement?

High-tensile ribbed PC wire offers superior tensile strength and bonding properties compared to traditional steel reinforcement bars, allowing for more efficient designs.

5. What best practices should be followed during the installation of high-tensile ribbed PC wire?

Proper handling, correct placement, and quality control measures are essential to ensure optimal performance and structural integrity during installation.

Conclusion

In conclusion, high-tensile ribbed PC wire is a pivotal material in modern construction, supporting the industry's need for durability, strength, and cost-effectiveness. Its unique properties enable architects and engineers to design innovative structures that stand the test of time. As the construction landscape continues to evolve, high-tensile ribbed PC wire will undoubtedly remain at the forefront, driving advancements and contributing to safer, more resilient buildings. Embracing this material can lead to a significant transformation in construction practices, ensuring that our built environment is robust, efficient, and sustainable.

Latest News

Understanding High-Tensile Ribbed PC Wire: A Key Component in Construction and Decoration

High-tensile ribbed PC wire, also known as prestressed concrete wire, is a specialized type of steel wire designed to provide superior strength and durability for various construction applications. This wire is commonly used in prestressed concrete structures, where its unique properties allow for enhanced load-bearing capabilities and reduced structural failures. One of the defining characterist

2025-12-13

Exploring the Benefits of Using High-Tensile Ribbed PC Wire in Structural Projects

Exploring the Benefits of Using High-Tensile Ribbed PC Wire in Structural Projects Table of Contents What is High-Tensile Ribbed PC Wire? Importance of High-Tensile Wire in Structural Engineering Key Advantages of Using High-Tensile Ribbed PC Wire Enhanced Durability Cost-Effectiveness Material Versatility Environmental Benefits Ap

2025-12-10

Understanding High-Tensile Ribbed PC Wire: A Key Player in Construction and Decoration

High-tensile ribbed PC wire, often referred to as prestressed concrete wire, plays a pivotal role in the construction and decoration materials sector, particularly within the realm of steel materials and wire ropes. This specialized wire is designed to withstand significant tensile stress, making it an ideal choice for reinforcing concrete structures. The ribbed texture of the wire enhances its bo

2025-12-07

Why High-Tensile Ribbed PC Wire is Essential for Modern Construction

Why High-Tensile Ribbed PC Wire is Essential for Modern Construction Table of Contents Introduction Understanding High-Tensile Ribbed PC Wire Benefits of High-Tensile Ribbed PC Wire Durability and Strength Corrosion Resistance Cost-Effectiveness Applications in Modern Construction Commercial Structures

2025-12-04

Understanding Spiral Prestressed Steel Wire: A Key Element in Modern Construction

Spiral prestressed steel wire is a cutting-edge material that plays a crucial role in modern construction and engineering applications. This specialized type of wire is designed to withstand high tensile stresses, offering enhanced performance in various structural elements. The unique spiral configuration allows for optimal energy distribution, making it ideal for applications requiring durabilit

2025-12-01

Why Choose Spiral Prestressed Steel Wire for Your Next Project?

Why Choose Spiral Prestressed Steel Wire for Your Next Project? Introduction to Spiral Prestressed Steel Wire In the ever-evolving world of construction and decoration materials, **spiral prestressed steel wire** has emerged as a revolutionary choice that combines strength, durability, and versatility. Its unique properties make it an ideal option for a variety of projects, from infrastructure dev

2025-11-28